Page 581 - IGUS Bearing

P. 581

iglidur J UV iglidur J UV

®

®

+90°C +90°C

35MPa 35MPa

Bearing technology | Plain bearings | iglidur J UV Technical data

®

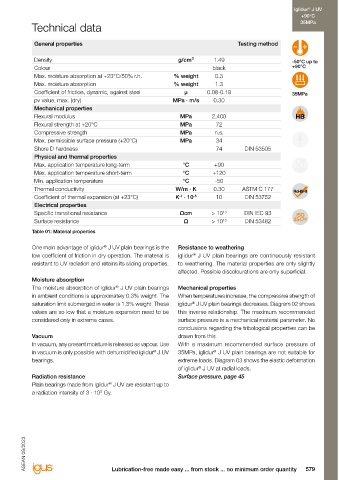

General properties Testing method

Density g/cm³ 1.49 -50°C up to

Ø Colour black +90°C

6.0-20.0mm

Max. moisture absorption at +23°C/50% r.h. % weight 0.3

Max. moisture absorption % weight 1.3

Coefficient of friction, dynamic, against steel µ 0.08-0.19 35MPa

pv value, max. (dry) MPa · m/s 0.30

Also available

as: Mechanical properties

For continuous direct sunlight Flexural modulus MPa 2,400

MPa

Flexural strength at +20°C

72

Permanently UV-resistant with properties Compressive strength MPa n.s.

Bar stock, Max. permissible surface pressure (+20°C) MPa 34

®

round bar comparable to iglidur J

Page 743 Shore D hardness 74 DIN 53505

Physical and thermal properties

Today, plain bearings appear as special shapes for special uses, in some instances of which they Max. application temperature long-term °C +90

are exposed to UV radiation for long periods of time. igus has therefore developed a new material: Max. application temperature short-term °C +120 FOOD

®

iglidur J UV. Min. application temperature °C -50

®

Bar stock, ● UV-stabilised Thermal conductivity W/m · K 0.30 ASTM C 177

plate ● Long-term mechanical properties improved -1 -5

Page 773 Coefficient of thermal expansion (at +23°C) K · 10 10 DIN 53752

● High wear resistance Electrical properties

Specific transitional resistance Ωcm > 10 13 DIN IEC 93

Typical application areas Surface resistance Ω > 10 13 DIN 53482

● Solar technology Table 01: Material properties

● Outdoor applications

tribo-tape liner

Page 781 One main advantage of iglidur J UV plain bearings is the Resistance to weathering

®

low coefficient of friction in dry operation. The material is iglidur J UV plain bearings are continuously resistant

®

resistant to UV radiation and retains its sliding properties. to weathering. The material properties are only slightly

affected. Possible discolourations are only superficial.

Moisture absorption

The moisture absorption of iglidur J UV plain bearings Mechanical properties

®

Guide rings

Page 641 in ambient conditions is approximately 0.3% weight. The When temperatures increase, the compressive strength of

®

saturation limit submerged in water is 1.3% weight. These iglidur J UV plain bearings decreases. Diagram 02 shows

Descriptive technical specifications values are so low that a moisture expansion need to be this inverse relationship. The maximum recommended

Wear resistance at +23°C – + considered only in extreme cases. surface pressure is a mechanical material parameter. No

conclusions regarding the tribological properties can be

Wear resistance at +90°C – +

Vacuum drawn from this.

Two hole Wear resistance at +150°C – + In vacuum, any present moisture is released as vapour. Use With a maximum recommended surface pressure of

flange

®

®

bearings in vacuum is only possible with dehumidified iglidur J UV 35MPa, iglidur J UV plain bearings are not suitable for

Page 667 Slide property – +

bearings. extreme loads. Diagram 03 shows the elastic deformation

Wear resistance under water – + of iglidur J UV at radial loads.

®

Radiation resistance Surface pressure, page 45

Media resistance – +

Plain bearings made from iglidur J UV are resistant up to

®

Moulded Resistant to edge pressures – + a radiation intensity of 3 · 10² Gy.

special parts

Page 696 Resistant to shock and impact loads – +

Dirt resistance – +

®

igubal Online product finder Online service life calculation

spherical balls

Page 993 www.igus-asean.com/iglidur-finder www.igus-asean.com/iglidur-expert ASEAN 09/2023 ASEAN 09/2023

578 3D-CAD, finder and service life calculation ... www.igus-asean.com/JUV Lubrication-free made easy ... from stock ... no minimum order quantity 579