Page 4 - Bosch Hot Water Boilers

P. 4

4 | Hot water boilers

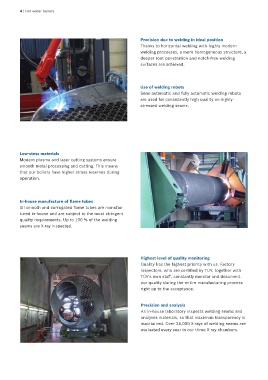

Precision due to welding in ideal position

Thanks to horizontal welding with highly modern

welding processes, a more homogeneous structure, a

deeper root penetration and notch-free welding

surfaces are achieved.

Use of welding robots

Semi-automatic and fully automatic welding robots

are used for consistently high quality on highly-

stressed welding seams.

Low-stess materials

Modern plasma and laser cutting systems ensure

smooth metal processing and cutting. This means

that our boilers have higher stress reserves during

operation.

In-house manufacture of flame tubes

All smooth and corrugated flame tubes are manufac-

tured in-house and are subject to the most stringent

quality requirements. Up to 100 % of the welding

seams are X-ray inspected.

Highest level of quality monitoring

Quality has the highest priority with us. Factory

inspectors, who are certified by TÜV, together with

TÜV's own staff, constantly monitor and document

our quality during the entire manufacturing process

right up to the acceptance.

Precision and analysis

An in-house laboratory inspects welding seams and

analyses materials, so that maximum transparency is

maintained. Over 25,000 X-rays of welding seams are

evaluated every year in our three X-ray chambers.