Page 933 - MiSUMi FA Mechanical Components Economy Series

P. 933

Economy Series

Instructions Cartridge Heaters

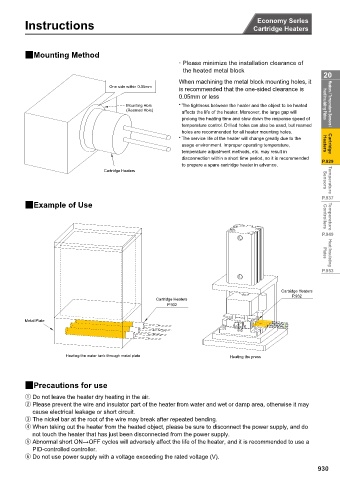

2Mounting Method

· Please minimize the installation clearance of

the heated metal block

20

When machining the metal block mounting holes, it

One side within 0.05mm

is recommended that the one-sided clearance is

0.05mm or less

Mounting Hole * The tightness between the heater and the object to be heated Heat Insulating Plates Heaters / Temperature Sensors /

(Reamed Hole) affects the life of the heater. Moreover, the large gap will

prolong the heating time and slow down the response speed of

temperature control. Drilled holes can also be used, but reamed

holes are recommended for all heater mounting holes.

* The service life of the heater will change greatly due to the

usage environment. Improper operating temperature, Heaters Cartridge

temperature adjustment methods, etc. may result in

disconnection within a short time period, so it is recommended P.929

to prepare a spare cartridge heater in advance.

Cartridge Heaters Sensors Temperature

P.937

2Example of Use Controllers Temperature

P.949

Plates

P.953

Heat Insulating

Cartridge Heaters

P.932

Cartridge Heaters

P.932

Metal Plate

Heating the water tank through metal plate Heating the press

2Precautions for use

Do not leave the heater dry heating in the air.

Please prevent the wire and insulator part of the heater from water and wet or damp area, otherwise it may

cause electrical leakage or short circuit.

The nickel bar at the root of the wire may break after repeated bending.

When taking out the heater from the heated object, please be sure to disconnect the power supply, and do

not touch the heater that has just been disconnected from the power supply.

Abnormal short ONĺOFF cycles will adversely affect the life of the heater, and it is recommended to use a

PID-controlled controller.

Do not use power supply with a voltage exceeding the rated voltage (V).

930