Page 130 - IGUS Bearing

P. 130

iglidur P210

®

+100°C

50MPa

Bearing technology | Plain bearings | iglidur P210

®

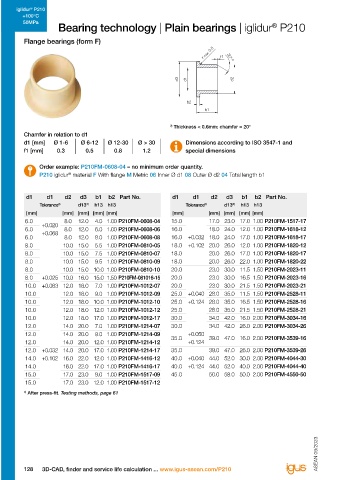

Flange bearings (form F)

r max. 0.5 f1 30°

d3 d1 d2

b2

b1

2) Thickness < 0.6mm: chamfer = 20°

Chamfer in relation to d1

d1 [mm] Ø 1-6 Ø 6-12 Ø 12-30 Ø > 30 Dimensions according to ISO 3547-1 and

f1 [mm] 0.3 0.5 0.8 1.2 special dimensions

Order example: P210FM-0608-04 – no minimum order quantity.

P210 iglidur material F With flange M Metric 06 Inner Ø d1 08 Outer Ø d2 04 Total length b1 The low-cost all-rounder

®

Well-balanced properties at a low price

d1 d1 d2 d3 b1 b2 Part No. d1 d1 d2 d3 b1 b2 Part No.

Tolerance 3) d13 3) h13 h13 Tolerance 3) d13 3) h13 h13

®

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] iglidur P230

6.0 +0.020 8.0 12.0 4.0 1.00 P210FM-0608-04 15.0 17.0 23.0 17.0 1.00 P210FM-1517-17

6.0 +0.068 8.0 12.0 6.0 1.00 P210FM-0608-06 16.0 18.0 24.0 12.0 1.00 P210FM-1618-12

6.0 8.0 12.0 8.0 1.00 P210FM-0608-08 16.0 +0.032 18.0 24.0 17.0 1.00 P210FM-1618-17

8.0 10.0 15.0 5.5 1.00 P210FM-0810-05 18.0 +0.102 20.0 26.0 12.0 1.00 P210FM-1820-12

8.0 10.0 15.0 7.5 1.00 P210FM-0810-07 18.0 20.0 26.0 17.0 1.00 P210FM-1820-17 When to use it?

8.0 10.0 15.0 9.5 1.00 P210FM-0810-09 18.0 20.0 26.0 22.0 1.00 P210FM-1820-22 ● When a cost-effective all-round bearing for high volumes is required

8.0 10.0 15.0 10.0 1.00 P210FM-0810-10 20.0 23.0 30.0 11.5 1.50 P210FM-2023-11 ● When a low-cost bearing with low moisture absorption is required

8.0 +0.025 10.0 16.0 15.0 1.50 P210FM-081016-15 20.0 23.0 30.0 16.5 1.50 P210FM-2023-16 ● When low pv values occur

10.0 +0.083 12.0 18.0 7.0 1.00 P210FM-1012-07 20.0 23.0 30.0 21.5 1.50 P210FM-2023-21

10.0 12.0 18.0 9.0 1.00 P210FM-1012-09 25.0 +0.040 28.0 35.0 11.5 1.50 P210FM-2528-11

10.0 12.0 18.0 10.0 1.00 P210FM-1012-10 25.0 +0.124 28.0 35.0 16.5 1.50 P210FM-2528-16

10.0 12.0 18.0 12.0 1.00 P210FM-1012-12 25.0 28.0 35.0 21.5 1.50 P210FM-2528-21 When not to use it?

10.0 12.0 18.0 17.0 1.00 P210FM-1012-17 30.0 34.0 42.0 16.0 2.00 P210FM-3034-16 ● When a cost-effective all-rounder for small quantities is required

®

12.0 14.0 20.0 7.0 1.00 P210FM-1214-07 30.0 34.0 42.0 26.0 2.00 P210FM-3034-26 iglidur G

12.0 14.0 20.0 9.0 1.00 P210FM-1214-09 35.0 +0.050 39.0 47.0 16.0 2.00 P210FM-3539-16 ● When high wear resistance is required

®

®

12.0 14.0 20.0 12.0 1.00 P210FM-1214-12 +0.124 iglidur G, iglidur G1

12.0 +0.032 14.0 20.0 17.0 1.00 P210FM-1214-17 35.0 39.0 47.0 26.0 2.00 P210FM-3539-26 ● When continuous operating temperatures are higher than +110°C

®

®

14.0 +0.102 16.0 22.0 12.0 1.00 P210FM-1416-12 40.0 +0.040 44.0 52.0 30.0 2.00 P210FM-4044-30 iglidur G, iglidur G1

14.0 16.0 22.0 17.0 1.00 P210FM-1416-17 40.0 +0.124 44.0 52.0 40.0 2.00 P210FM-4044-40

15.0 17.0 23.0 9.0 1.00 P210FM-1517-09 45.0 50.0 58.0 50.0 2.00 P210FM-4550-50

15.0 17.0 23.0 12.0 1.00 P210FM-1517-12

3) After press-fit. Testing methods, page 61

ASEAN 09/2023 ASEAN 09/2023

128 3D-CAD, finder and service life calculation ... www.igus-asean.com/P210