Page 21 - IGUS Bearing

P. 21

Sustainable

product

development

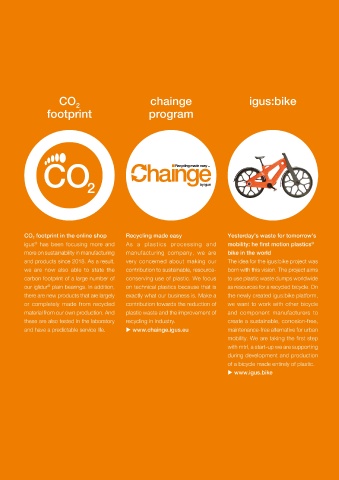

Plastic is a much-discussed material. We know that high- ECO CO chainge igus:bike

performance polymers can make a contribution to the 2

protection of resources and to the environment, and have product range footprint program

made this the focus of our activities. We look at plastics in

three phases: during production, in use and at the end of the

product's life. We will give you our answers to sustainability

questions for both our products and everyday life at igus .

®

Much remains unanswered, and for some things, especially

with regard to sustainable production, we are still working 100

on answers and solutions.

regranulate

u www.igus-asean.com/sustainability

Cost-effective and versatile. CO 2 footprint in the online shop Recycling made easy Yesterday's waste for tomorrow's

The new, sustainable iglidur ECO igus has been focusing more and As a plastics processing and mobility: he first motion plastics

®

®

®

materials consist of regranulates of more on sustainability in manufacturing manufacturing company, we are bike in the world

our top materials, which have proven and products since 2018. As a result, very concerned about making our The idea for the igus:bike project was

themselves for many years. we are now also able to state the contribution to sustainable, resource- born with this vision. The project aims

carbon footprint of a large number of conserving use of plastic. We focus to use plastic waste dumps worldwide

our iglidur plain bearings. In addition, on technical plastics because that is as resources for a recycled bicycle. On

®

there are new products that are largely exactly what our business is. Make a the newly created igus:bike platform,

or completely made from recycled contribution towards the reduction of we want to work with other bicycle

material from our own production. And plastic waste and the improvement of and component manufacturers to

these are also tested in the laboratory recycling in industry. create a sustainable, corrosion-free,

and have a predictable service life. u www.chainge.igus.eu maintenance-free alternative for urban

mobility. We are taking the first step

with mtrl, a start-up we are supporting

during development and production

of a bicycle made entirely of plastic.

u www.igus.bike

18 19