Page 605 - IGUS Bearing

P. 605

iglidur J2 iglidur J2

®

®

+90°C +90°C

46MPa 46MPa

Bearing technology | Plain bearings | iglidur J2 Technical data

®

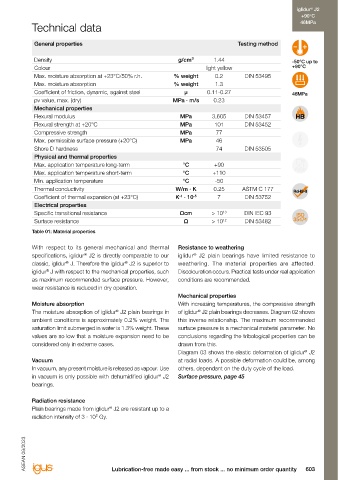

General properties Testing method

Density g/cm³ 1.44 -50°C up to

Ø Colour light yellow +90°C

6.0-25.0mm

Max. moisture absorption at +23°C/50% r.h. % weight 0.2 DIN 53495

Max. moisture absorption % weight 1.3

Coefficient of friction, dynamic, against steel µ 0.11-0.27 46MPa

pv value, max. (dry) MPa · m/s 0.23

Also available

as: Mechanical properties

Versatile and cost-effective Flexural modulus MPa 3,605 DIN 53457

MPa

Flexural strength at +20°C

DIN 53452

101

For applications with infrequent movement or Compressive strength MPa 77

Bar stock, Max. permissible surface pressure (+20°C) MPa 46

round bar continuous lubrication

Page 743 Shore D hardness 74 DIN 53505

Physical and thermal properties

iglidur J2 has good universal media resistance, comparable to that of iglidur J and similar materials. Max. application temperature long-term °C +90

®

®

The mechanical specifications in sporadically moving applications are better, but in comparison there are Max. application temperature short-term °C +110 FOOD

significant reductions in friction and wear. Like all iglidur materials, iglidur J2 is PFOA-free. Min. application temperature °C -50

®

®

Bar stock, ● Robust Thermal conductivity W/m · K 0.25 ASTM C 177

plate ● Cost-effective -1 -5

Page 773 Coefficient of thermal expansion (at +23°C) K · 10 7 DIN 53752

● High media resistance Electrical properties

● Lubrication-free Specific transitional resistance Ωcm > 10 13 DIN IEC 93

● Maintenance-free Surface resistance Ω > 10 12 DIN 53482

Table 01: Material properties

Typical application areas

tribo-tape liner

Page 781 ● Jig construction With respect to its general mechanical and thermal Resistance to weathering

● Industrial handling

specifications, iglidur J2 is directly comparable to our iglidur J2 plain bearings have limited resistance to

®

®

classic, iglidur J. Therefore the iglidur J2 is superior to weathering. The material properties are affected.

®

®

iglidur J with respect to the mechanical properties, such Discolouration occurs. Practical tests under real application

®

as maximum recommended surface pressure. However, conditions are recommended.

wear resistance is reduced in dry operation.

Guide rings

Page 641 Mechanical properties

Moisture absorption With increasing temperatures, the compressive strength

Descriptive technical specifications The moisture absorption of iglidur J2 plain bearings in of iglidur J2 plain bearings decreases. Diagram 02 shows

®

®

Wear resistance at +23°C – + ambient conditions is approximately 0.2% weight. The this inverse relationship. The maximum recommended

saturation limit submerged in water is 1.3% weight. These surface pressure is a mechanical material parameter. No

Wear resistance at +90°C – +

values are so low that a moisture expansion need to be conclusions regarding the tribological properties can be

Two hole Wear resistance at +150°C – + considered only in extreme cases. drawn from this.

flange

®

bearings Diagram 03 shows the elastic deformation of iglidur J2

Page 667 Slide property – +

Vacuum at radial loads. A possible deformation could be, among

Wear resistance under water – + In vacuum, any present moisture is released as vapour. Use others, dependant on the duty cycle of the load.

in vacuum is only possible with dehumidified iglidur J2 Surface pressure, page 45

®

Media resistance – +

bearings.

Moulded Resistant to edge pressures – +

special parts Radiation resistance

Page 696 Resistant to shock and impact loads – +

®

Plain bearings made from iglidur J2 are resistant up to a

Dirt resistance – + radiation intensity of 3 · 10² Gy.

igubal Online product finder Online service life calculation

®

spherical balls

Page 993 www.igus-asean.com/iglidur-finder www.igus-asean.com/iglidur-expert ASEAN 09/2023 ASEAN 09/2023

602 3D-CAD, finder and service life calculation ... www.igus-asean.com/J2 Lubrication-free made easy ... from stock ... no minimum order quantity 603