Page 187 - MiSUMi FA Mechanical Components Economy Series

P. 187

Economy Series

[Technical Calculation] Cable Carriers Technical Calculation For Cable Carriers

2What is the Cable Carrier?

· It can prevent the cable and wire tubes connected to the moving parts of the equipment from twisting, stretching and entanglement

due to movement.

· It is suitable for supporting and guiding multiple cables connected to the linear motion part.

· MISUMI Cable Carrier can be ordered simply by specifying the applicable single type and no need to select the part numbers for the

link and mounting bracket, respectively.

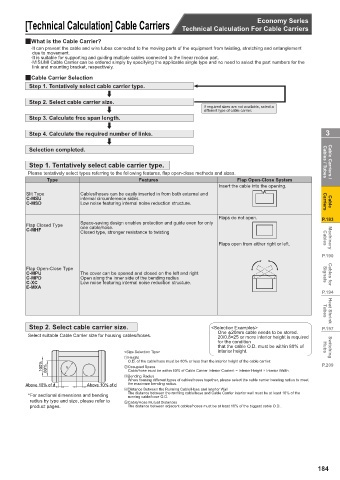

2Cable Carrier Selection

Step 1. Tentatively select cable carrier type.

Step 2. Select cable carrier size.

If required sizes are not available, select a

diff erent type of cable carrier.

Step 3. Calculate free span length.

Step 4. Calculate the required number of links. 3

Selection completed.

Step 1. Tentatively select cable carrier type. Cables / Tubes Cable Carriers /

Please tentatively select types referring to the following features, fl ap open-close methods and sizes.

Type Features Flap Open-Close System

Insert the cable into the opening.

Slit Type Cables/hoses can be easily inserted in from both external and

C-MSU internal circumference sides.

C-MSD Low noise featuring internal noise reduction structure. Carriers Cable

Flaps do not open. P.183

Flap Closed Type Space-saving design enables protection and guide even for only

one cable/hose.

C-MHF Closed type, stronger resistance to twisting

Flaps open from either right or left. Cables Machinery

P.190

Flap Open-Close Type

C-MPU The cover can be opened and closed on the left and right Signals Cables for

C-MPD Open along the inner side of the bending radius

C-XC Low noise featuring internal noise reduction structure.

E-MXA

P.194

Tubes

Step 2. Select cable carrier size. <Selection Examples> P.197

Heat Shrink

One П20mm cable needs to be stored.

Select suitable Cable Carrier size for housing cables/hoses. 20/0.8=25 or more interior height is required

for the condition

that the cable O.D. must be within 80% of Hubs Switching

<Size Selection Tips> interior height.

Height

O.D. of the cable/hose must be 80% or less than the interior height of the cable carrier.

100% 80% d Occupied Space P.209

Cable/hose must be within 60% of Cable Carrier Interior Content = Interior Height × Interior Width.

Bending Radius

When housing diff erent types of cables/hoses together, please select the cable carrier bending radius to meet

Above 10% of d Above 10% of d the maximum bending radius.

Distance Between the Running Cable/Hose and Interior Wall

* For sectional dimensions and bending The distance between the running cable/hose and Cable Carrier interior wall must be at least 10% of the

running cable/hose O.D.

radius by type and size, please refer to Cable/Hose Mutual Distances

product pages. The distance between adjacent cables/hoses must be at least 10% of the biggest cable O.D..

184