Page 394 - IGUS Bearing

P. 394

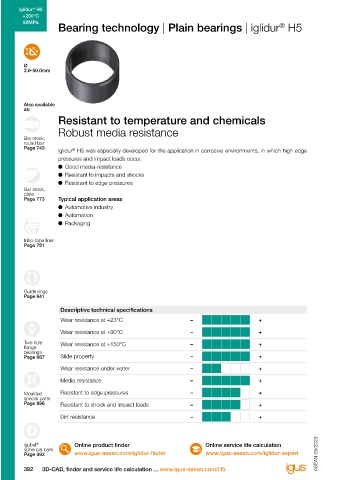

iglidur H5 iglidur H5

®

®

+200°C +200°C

80MPa 80MPa

Bearing technology | Plain bearings | iglidur H5 Technical data

®

General properties Testing method

Density g/cm³ 1.41 -40°C up to

Ø Colour black +200°C

3.0-50.0mm

Max. moisture absorption at +23°C/50% r.h. % weight 0.1 DIN 53495

Max. moisture absorption % weight 0.7

Coefficient of friction, dynamic, against steel µ 0.08-0.24 80MPa

pv value, max. (dry) MPa · m/s 0.7

Also available

as: Mechanical properties

Resistant to temperature and chemicals Flexural modulus MPa 6,400 DIN 53457

DIN 53452

150

MPa

Flexural strength at +20°C

Robust media resistance Compressive strength MPa n.s.

Bar stock, Max. permissible surface pressure (+20°C) MPa 80

round bar

Page 743 Shore D hardness 72 DIN 53505

iglidur H5 was especially developed for the application in corrosive environments, in which high edge

®

pressures and impact loads occur. Physical and thermal properties

● Good media-resistance Max. application temperature long-term °C +200 FOOD

● Resistant to impacts and shocks Max. application temperature short-term °C +240

● Resistant to edge pressures Min. application temperature °C up to -40

Bar stock, Thermal conductivity W/m · K 0.25 ASTM C 177

plate -1 -5

Page 773 Typical application areas Coefficient of thermal expansion (at +23°C) K · 10 7 DIN 53752

● Automotive industry Electrical properties

● Automation Specific transitional resistance Ωcm n.s. DIN IEC 93

● Packaging Surface resistance Ω > 10 12 DIN 53482

Table 01: Material properties

tribo-tape liner

Page 781 iglidur H5 plain bearings stand for high carrying capacity, Radiation resistance

®

good abrasion resistance and good temperature Plain bearings made from iglidur H5 are resistant up to a

®

resistance, besides the obvious economic factors. radiation intensity of 2 · 10² Gy.

Temperatures up to +200°C, permitted surface pressure

up to 65MPa, and excellent chemical resistance are only Resistance to weathering

some of the essential attributes. Solid lubricants reduce iglidur H5 plain bearings are continuously resistant

®

Guide rings

Page 641 the coefficient of friction and support the wear resistance, to weathering. The material properties are only slightly

which has been significantly improved compared to the affected. Possible discolourations are only superficial.

Descriptive technical specifications iglidur H3 plain bearings, which are also very cost-effective.

®

Wear resistance at +23°C – + iglidur H5 plain bearings are suitable for all sliding Mechanical properties

®

surfaces. With increasing temperatures, the compressive strength of

Wear resistance at +90°C – +

iglidur H5 plain bearings decreases. Diagram 02 shows

®

Two hole Wear resistance at +150°C – + Moisture absorption this inverse relationship. The maximum recommended

flange

bearings The moisture absorption of iglidur H5 plain bearings is surface pressure is a mechanical material parameter. No

®

Page 667 Slide property – +

below 0.1% weight in ambient conditions. The saturation conclusions regarding the tribological properties can be

Wear resistance under water – + limit submerged in water is 0.7% weight. iglidur H5 is drawn from this.

®

therefore an ideal material for wet environments. Diagram 03 shows the elastic deformation of iglidur H5

®

Media resistance – +

at radial loads.

Moulded Resistant to edge pressures – + Vacuum Surface pressure, page 45

special parts In vacuum, any present moisture is released as vapour.

Page 696 Resistant to shock and impact loads – +

The use in vacuum is generally possible.

Dirt resistance – +

®

igubal Online product finder Online service life calculation

spherical balls

Page 993 www.igus-asean.com/iglidur-finder www.igus-asean.com/iglidur-expert ASEAN 09/2023 ASEAN 09/2023

392 3D-CAD, finder and service life calculation ... www.igus-asean.com/H5 Lubrication-free made easy ... from stock ... no minimum order quantity 393