Page 397 - IGUS Bearing

P. 397

iglidur H5 iglidur H5

®

®

+200°C +200°C

80MPa 80MPa

Bearing technology | Plain bearings | iglidur H5 Technical data

®

Permissible surface speeds Chemicals Resistance 100.0 0.7

In contrast to the similarly cost-effective iglidur H3 Alcohols + 10.0 0.6

®

plain bearings, iglidur H5 has a favourable coefficient Diluted acids + up to 0 0.5

®

of friction. This accounts for the higher permitted surface Diluted alkalines + 1.0 0.4

speeds that can be attained with these bearings. The Fuels + 0.3

speeds stated in table 03 are limit values for the lowest Greases, oils without additives + Surface pressure [MPa] 0.1 Coefficient of friction [µ] 0.2

bearing loads. With higher loads, the permitted speed Hydrocarbons + 0.1

drops with the extent of the load due to the limitations Strong acids 0 up to – 0.01 0.001 0.01 0.1 1.0 10.0 0.0

by the pv value. Strong alkalines + 0 10 20 30 40 50 60 70 80

Surface speed, page 48 Surface speed [m/s] Load [MPa]

All data given at room temperature [+20°C]

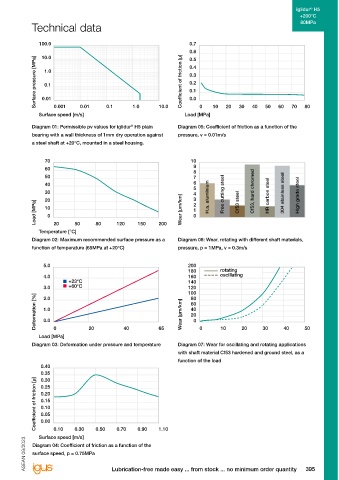

Diagram 01: Permissible pv values for iglidur H5 plain Diagram 05: Coefficient of friction as a function of the

®

Table 02: Chemical resistance

Temperature Chemical table, page 1170 bearing with a wall thickness of 1mm dry operation against pressure, v = 0.01m/s

iglidur H5 is an extremely temperature-resistant material. a steel shaft at +20°C, mounted in a steel housing.

®

With increasing temperatures, the compressive strength Rotating Oscillating linear

of iglidur H5 plain bearings decreases. When considering Long-term m/s 1.0 0.7 4.0 70 10

®

temperatures, the additional frictional heat in the bearing Short-term m/s 1.5 1.1 6.0 60 9

system must be taken into account. For temperatures over 50 8

7

+80°C an additional securing is required. Table 03: Maximum surface speeds 40 6

Application temperatures, page 53 Dry Greases Oil Water 30 5 Free cutting steel Cf53, hard chromed 304 stainless steel

4

Additional securing, page 53 20 3 H.a. aluminium HR carbon steel High grade steel

Coefficient of friction μ 0.08-0.24 0.09 0.04 0.04 2 Cf53 steel

Table 04: Coefficient of friction against steel (Ra = 1μm, Load [MPa] 10 Wear [µm/km] 1

Friction and wear 0 0

The coefficient of friction of the iglidur H5 plain bearings 50HRC) 20 50 80 120 150 200

®

is very low (diagrams 04 and 05). Please note that a sliding Housing Plain bearings Shaft Temperature [°C]

surface with a rough surface finish will increase the friction. Ø d1 [mm] H7 [mm] F10 [mm] h9 [mm] Diagram 02: Maximum recommended surface pressure as a Diagram 06: Wear, rotating with different shaft materials,

Coefficient of friction and surfaces, page 51 0-3 +0.000 +0.010 +0.006 +0.046 -0.025 +0.000 function of temperature (65MPa at +20°C) pressure, p = 1MPa, v = 0.3m/s

Wear resistance, page 54

> 3-6 +0.000 +0.012 +0.010 +0.058 -0.030 +0.000

> 6-10 +0.000 +0.015 +0.013 +0.071 -0.036 +0.000 5.0 200

Shaft materials > 10-18 +0.000 +0.018 +0.016 +0.086 -0.043 +0.000 180 rotating

oscillating

With many of the suitable shaft materials, iglidur H5 is the > 18-30 +0.000 +0.021 +0.020 +0.104 -0.052 +0.000 4.0 +23°C 160

®

140

economical alternative to many other high-temperature > 30-50 +0.000 +0.025 +0.025 +0.125 -0.062 +0.000 3.0 +60°C 120

bearings. The important thing is however the selection of > 50-80 +0.000 +0.030 +0.030 +0.150 -0.074 +0.000 2.0 100

80

the suitable shaft material. It cannot be generally stated that > 80-120 +0.000 +0.035 -0.036 +0.176 -0.087 +0.000 60

iglidur H5 is suitable for use with hard or soft shafts. Tests > 120-180 +0.000 +0.040 +0.043 +0.203 +0.000 +0.100 Deformation [%] 1.0 Wear [µm/km] 40

®

20

have however shown that pivoting applications yield better 0.0 0

wear data. In rotating applications, the wear increases Table 05: Important tolerances for plain bearings according 0 20 40 65 0 10 20 30 40 50

markedly from 10MPa. to ISO 3547-1 after press-fit Load [MPa]

Shaft materials, page 56 Diagram 03: Deformation under pressure and temperature Diagram 07: Wear for oscillating and rotating applications

with shaft material Cf53 hardened and ground steel, as a

Installation tolerances function of the load

iglidur H5 plain bearings are standard bearings for shafts 0.40

®

with h-tolerance (recommended minimum h9). After 0.35

0.30

being assembled into a nominal size housing, in standard 0.25

cases the inner diameter automatically adjusts to the F10 0.20

tolerances. For particular dimensions the tolerance differs Coefficient of friction [µ] 0.15

depending on the wall thickness (please see product range 0.10

table). 0.05

Testing methods, page 61 0.00 0.10 0.30 0.50 0.70 0.90 1.10

Surface speed [m/s]

ASEAN 09/2023 ASEAN 09/2023 surface speed, p = 0.75MPa

Diagram 04: Coefficient of friction as a function of the

394 3D-CAD, finder and service life calculation ... www.igus-asean.com/H5 Lubrication-free made easy ... from stock ... no minimum order quantity 395