Page 447 - IGUS Bearing

P. 447

iglidur A160 iglidur A160

®

®

+90°C +90°C

15MPa 15MPa

Bearing technology | Plain bearings | iglidur A160 Technical data

®

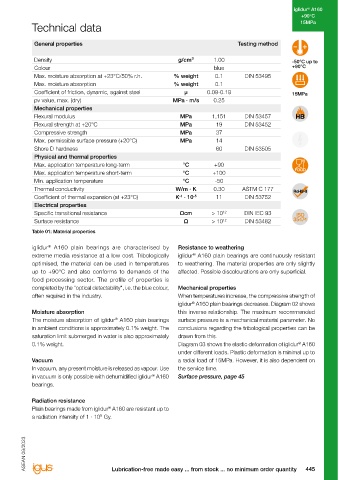

General properties Testing method

Density g/cm³ 1.00 -50°C up to

Ø Colour blue +90°C

6.0-20.0mm

Max. moisture absorption at +23°C/50% r.h. % weight 0.1 DIN 53495

Max. moisture absorption % weight 0.1

Coefficient of friction, dynamic, against steel µ 0.09-0.19 15MPa

pv value, max. (dry) MPa · m/s 0.25

Also available

as: Mechanical properties

Food bearing with media resistance up to Flexural modulus MPa 1,151 DIN 53457

MPa

Flexural strength at +20°C

DIN 53452

19

+90°C Compressive strength MPa 37

Bar stock, Max. permissible surface pressure (+20°C) MPa 14

round bar Compliant with Regulation (EU) No. 10/2011

Page 743 Shore D hardness 60 DIN 53505

and FDA guidelines Physical and thermal properties

Max. application temperature long-term °C +90

FOOD

iglidur A160 offers maximum media resistance in the medium temperature range and is therefore a true Max. application temperature short-term °C +100

®

®

low-cost iglidur . The profile of properties is completed by the suitability for applications in the food industry. Min. application temperature °C -50

Bar stock, ● Compliant with Regulation (EU) No. 10/2011 Thermal conductivity W/m · K 0.30 ASTM C 177

plate -1 -5

Page 773 ● FDA-compliant Coefficient of thermal expansion (at +23°C) K · 10 11 DIN 53752

● High media resistance Electrical properties

● Cost-effective Specific transitional resistance Ωcm > 10 12 DIN IEC 93

● Lubrication-free Surface resistance Ω > 10 12 DIN 53482

● Maintenance-free Table 01: Material properties

tribo-tape liner

Page 781 Typical application areas iglidur A160 plain bearings are characterised by Resistance to weathering

®

®

● Food industry extreme media resistance at a low cost. Tribologically iglidur A160 plain bearings are continuously resistant

● Beverage technology optimised, the material can be used in temperatures to weathering. The material properties are only slightly

● Medical technology up to +90°C and also conforms to demands of the affected. Possible discolourations are only superficial.

food processing sector. The profile of properties is

completed by the "optical detectability", i.e. the blue colour, Mechanical properties

Guide rings

Page 641 often required in the industry. When temperatures increase, the compressive strength of

®

iglidur A160 plain bearings decreases. Diagram 02 shows

Descriptive technical specifications Moisture absorption this inverse relationship. The maximum recommended

Wear resistance at +23°C – + The moisture absorption of iglidur A160 plain bearings surface pressure is a mechanical material parameter. No

®

in ambient conditions is approximately 0.1% weight. The conclusions regarding the tribological properties can be

Wear resistance at +90°C – +

saturation limit submerged in water is also approximately drawn from this.

Two hole Wear resistance at +150°C – + 0.1% weight. Diagram 03 shows the elastic deformation of iglidur A160

®

flange

bearings under different loads. Plastic deformation is minimal up to

Page 667 Slide property – +

Vacuum a radial load of 15MPa. However, it is also dependent on

Wear resistance under water – + In vacuum, any present moisture is released as vapour. Use the service time.

in vacuum is only possible with dehumidified iglidur A160 Surface pressure, page 45

®

Media resistance – +

bearings.

Moulded Resistant to edge pressures – +

special parts Radiation resistance

Page 696 Resistant to shock and impact loads – +

Plain bearings made from iglidur A160 are resistant up to

®

Dirt resistance – + a radiation intensity of 1 · 10⁵ Gy.

®

igubal Online product finder Online service life calculation

spherical balls

Page 993 www.igus-asean.com/iglidur-finder www.igus-asean.com/iglidur-expert ASEAN 09/2023 ASEAN 09/2023

444 3D-CAD, finder and service life calculation ... www.igus-asean.com/A160 Lubrication-free made easy ... from stock ... no minimum order quantity 445