Page 365 - IGUS Linear

P. 365

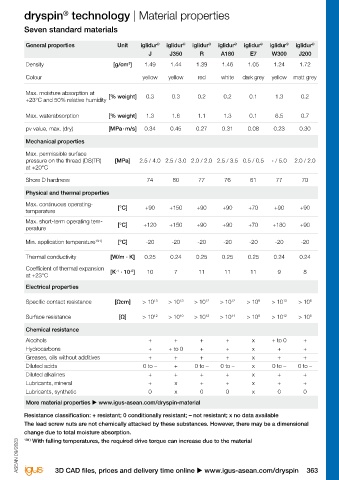

dryspin technology | Material properties dryspin technology | Material properties

®

®

More combinations available in the thread section Seven standard materials

The right lead screw nut material for General properties Unit iglidur iglidur iglidur iglidur iglidur iglidur iglidur

®

®

®

®

®

®

®

A180

R

J200

W300

E7

J350

J

every technical requirement Density [g/cm ] 1.49 1.44 1.39 1.46 1.05 1.24 1.72

3

Colour yellow yellow red white dark grey yellow matt grey

dryspin lead screw nuts are available in the standard coefficients. These are made up of various components:

®

range for every technical requirement. The range includes base polymer for greater wear resistance, fibres and fillers Max. moisture absorption at [% weight] 0.3 0.3 0.2 0.2 0.1 1.3 0.2

lead screw nuts made from seven lubrication-free iglidur reinforce the components to absorb high forces. Solid +23°C and 50% relative humidity

®

high-performance polymers, in cylindrical type or flange lubricants in our materials mean that the components Max. water absorption [% weight] 1.3 1.6 1.1 1.3 0.1 6.5 0.7

variants. The iglidur plastics enable the cost-effective made from them are self-lubricating and thus reduce

®

production of components for moving applications and the friction of the system and reduce wear. With the use pv value, max. (dry) [MPa · m/s] 0.34 0.45 0.27 0.31 0.08 0.23 0.30

are ideally suited for the production of prototypes and high of iglidur materials you increase the service life of your Mechanical properties

®

volume requirements. Due to its specifications, each material components and reduce costs and maintenance. It doesn't

becomes a specialist for a specific area of application. matter whether it's a standard solution from the catalogue Max. permissible surface

The right iglidur materials are available for almost every product range or your lead screw nut in the desired shape, pressure on the thread (DS(TR) [MPa] 2.5 / 4.0 2.5 / 3.0 2.0 / 2.0 2.5 / 3.5 0.5 / 0.5 - / 5.0 2.0 / 2.0

®

application from high temperatures to seawater, from food desired quantity and desired material, manufactured by us at +20°C

to automotive . All materials have been specially developed according to your drawing. Shore D hardness 74 80 77 76 61 77 70

for dynamic applications and have low friction and wear

Physical and thermal properties

Max. continuous operating -

● Lubrication and maintenance-free Find and calculate suitable temperature [°C] +90 +150 +90 +90 +70 +90 +90

● Calculate service life online lead screw drives Max. short-term operating tem-

● No minimum order value u www.igus-asean.com/leadscrewdrives-finder perature [°C] +120 +150 +90 +90 +70 +180 +90

● No minimum order quantity

Min. application temperature 191) [°C] -20 -20 -20 -20 -20 -20 -20

Thermal conductivity [W/m · K] 0.25 0.24 0.25 0.25 0.25 0.24 0.24

Coefficient of thermal expansion [K · 10 ] 10 7 11 11 11 9 8

-5

-1

Correct choice of material at +23°C

Electrical properties

iglidur A180 iglidur A180

®

®

iglidur E7 iglidur E7 Specific cont act resistance [Ωcm] > 10 13 > 10 13 > 10 12 > 10 12 > 10 9 > 10 13 > 10 8

®

®

iglidur J iglidur J

®

®

iglidur J200 iglidur J200 Surface resistance [Ω] > 10 12 > 10 10 > 10 12 > 10 11 > 10 9 > 10 12 > 10 8

®

®

iglidur J350 iglidur J350 Chemical resistance

®

®

iglidur R iglidur R Alcohols + + + + x + to 0 +

®

®

0 10 50 150 200 400 500 1,000 0 10 25 50 90 150 200 250

Hydrocarbons + + to 0 + + x + +

Speed [rpm] Temperature [°C] Greases, oils without additives + + + + x + +

Diluted acids 0 to – + 0 to – 0 to – x 0 to – 0 to –

Diluted alkalines + + + + x + +

iglidur A180 iglidur A180 Lubricants, mineral + x + + x + +

®

®

iglidur E7 iglidur E7 Lubricants, synthetic 0 x 0 0 x 0 0

®

®

iglidur J iglidur J

®

®

iglidur J200 iglidur J200 More material properties u www.igus-asean.com/dryspin-material

®

®

iglidur J350 iglidur J350 Resistance classification: + resistant; 0 conditionally resistant; – not resistant; x no data available

®

®

iglidur R iglidur R The lead screw nuts are not chemically attacked by these substances. However, there may be a dimensional

®

®

0 1 2 3 4 5 0 0.1 0.15 0.2 0.25 0.3 0.35 0.4 change due to total moisture absorption.

Surface pressure in the thread [MPa] Coefficient of friction [µ] 191) With falling temperatures, the required drive torque can increase due to the material

iglidur J200 most suitable in combination with hard anodised aluminium ASEAN 09/2023 ASEAN 09/2023

®

362 Online tools and more information u www.igus-asean.com/dryspin 3D CAD files, prices and delivery time online u www.igus-asean.com/dryspin 363