Page 117 - MiSUMi FA Mechanical Components Economy Series

P. 117

Economy Series

Miniature Linear Guides

2Installation of slide rail

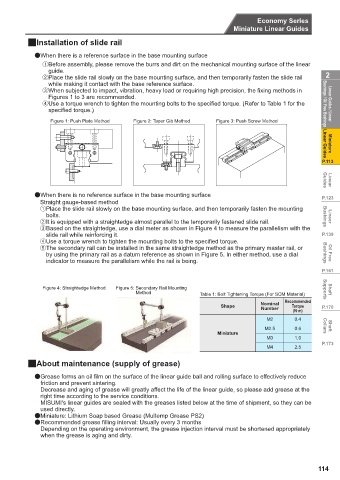

*When there is a reference surface in the base mounting surface

Before assembly, please remove the burrs and dirt on the mechanical mounting surface of the linear

guide.

Place the slide rail slowly on the base mounting surface, and then temporarily fasten the slide rail 2

while making it contact with the base reference surface.

When subjected to impact, vibration, heavy load or requiring high precision, the fixing methods in

Figures 1 to 3 are recommended.

Use a torque wrench to tighten the mounting bolts to the specified torque. (Refer to Table 1 for the Bushings / Oil Free Bushings Linear Guides / Linear

specified torque.)

Figure 1: Push Plate Method Figure 2: Taper Gib Method Figure 3: Push Screw Method

Miniature

Linear Guides

P.113

Guides

Linear

*When there is no reference surface in the base mounting surface P.123

Straight gauge-based method

Place the slide rail slowly on the base mounting surface, and then temporarily fasten the mounting

bolts. Bushings Linear

It is equipped with a straightedge almost parallel to the temporarily fastened slide rail.

Based on the straightedge, use a dial meter as shown in Figure 4 to measure the parallelism with the

slide rail while reinforcing it. P.139

Use a torque wrench to tighten the mounting bolts to the specified torque.

The secondary rail can be installed in the same straightedge method as the primary master rail, or

by using the primary rail as a datum reference as shown in Figure 5. In either method, use a dial Bushings Oil Free

indicator to measure the parallelism while the rail is being.

P.161

Figure 4: Straightedge Method Figure 5: Secondary Rail Mounting Supports Shaft

Method Table 1: Bolt Tightening Torque (For SCM Material)

Nominal Recommended

Shape Torque P.170

Number (N·m)

M2 0.4

M2.5 0.6 Collars Shaft

Miniature

M3 1.0

P.173

M4 2.5

2About maintenance (supply of grease)

* Grease forms an oil film on the surface of the linear guide ball and rolling surface to effectively reduce

friction and prevent sintering.

Decrease and aging of grease will greatly affect the life of the linear guide, so please add grease at the

right time according to the service conditions.

MISUMI's linear guides are sealed with the greases listed below at the time of shipment, so they can be

used directly.

*Miniature: Lithium Soap based Grease (Multemp Grease PS2)

* Recommended grease filling interval: Usually every 3 months

Depending on the operating environment, the grease injection interval must be shortened appropriately

when the grease is aging and dirty.

114