Page 59 - MiSUMi FA Mechanical Components Economy Series

P. 59

1

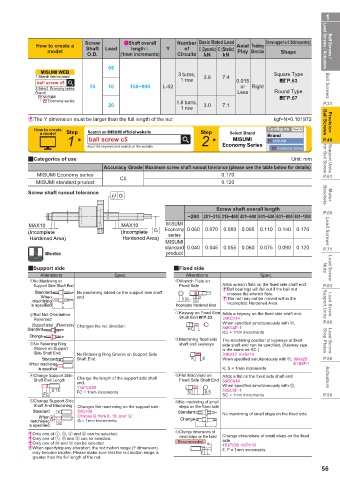

Screw Shaft overall Number Basic Rated Load Screw support unit (Sold separately)

How to create a Shaft Lead length L Y of Axial Twisting Lead Screws / Actuators Ball Screws /

model C (Dynamic) C (Static) Play Direction Shape

O.D. (1mm increments) Circuits kN kN

05

MISUMI WEB

1.Search this keyword 3 turns, 3.6 7.4 Square Type

ball screw c5 1 row 0.015 % P.63

2.Select Economy series 15 10 150~900 L-62 or Right Ball Screws

Brand Less Round Type

MISUMI % P.67

Economy series 1.8 turns,

20 3.0 7.1 P.31

1 row

& The Y dimension must be larger than the full length of the nut kgf=N×0.101972 Ball Screws Precision

How to create Configure Clear All

a model Step Search on MISUMI official website Step Select Brand Brand

1 ball screw c5 2 MISUMI MISUMI P.49

Economy Series

Input the keyword and search on the website

Economy series

2Categories of use Unit: mm for Ball Screw Support Units

Accuracy Grade Maximum screw shaft runout tolerance (please see the table below for details)

MISUMI Economy series 0.170 P.61

C5

MISUMI standard product 0.120

Screw shaft runout tolerance

G Brackets Motor

Screw shaft overall length

P.69

~200 201~315 315~400 401~500 501~630 631~800 801~1000

MAX10 MAX10 MISUMI

(Incomplete (Incomplete G Economy 0.060 0.070 0.080 0.095 0.110 0.140 0.170 Lead Screws

series

Hardened Area) Hardened Area)

MISUMI

standard 0.040 0.045 0.055 0.060 0.075 0.090 0.120 P.71

Alteration product

2Support side 2Fixed side Nuts Lead Screw

Alterations Spec. Alterations Spec.

No Machining on Wrench Flats on

Support Side Shaft End Fixed Side Adds wrench fl ats on the fi xed side shaft end. P.83

Standard No machining added on the support side shaft & Ball bearings will fall out if the ball nut

crosses the wrench flats.

When end. 7 5

0

machining 10 -0.2 32 & The nut may not be moved within the

is specified L Incomplete Hardened Area Incomplete Hardened Area. Support Units Lead Screw

Ball Nut Orientation Keyway on Fixed Side Adds a keyway on the fi xed side shaft end.

Shaft End %P.33

Reversed 3≤KC≤14

(Support side) (Fixed side) Changes the nut direction. When specifi ed simultaneously with 2, P.86

Standard KC 3≤KC≤F-1

KC = 1mm increments

Change

Machining fi xed side The machining position of keyways at fi xed Stop Plates

No Retaining Ring shaft end keyways side shaft end can be specifi ed. (Keyway size Lead Screw

Groove on Support is the same as KC.)

Side Shaft End No Retaining Ring Groove on Support Side 3≤K≤13 K+S≤14

Standard Shaft End. K S When specifi ed simultaneously with 2, 3≤K≤28 P.90

When machining K+S≤F-1

is specified K, S = 1mm increments

Change Support Side Change the length of the support side shaft Flat Machined on Adds a fl at on the fi xed side shaft end Actuators

Shaft End Length Fixed Side Shaft End 5≤SC≤14

end.

11≤FC≤30 When specifi ed simultaneously with 2,

9.15 5≤SC≤F-1

FC FC = 1mm increments SC 0.5 SC = 1mm increments P.99

Change Support Side No machining of small

Shaft End Machining Changes the machining on the support side. steps on the fi xed side

Standard 5≤G≤36 Standard No machining of small steps on the fi xed side

When Qh7 Choose Q from 8, 10, and 12 Change

machining G G = 1mm increments

is specified L

& Only one of , , and can be selected. 2 Change dimensions of Change dimensions of small steps on the fi xed

& Only one of , and can be selected. small steps on the fi xed side

side

& Only one of and 2 can be selected Recommended P 15≤F≤30 6≤P≤10

& When specifying any alteration, the nut motion range (Y dimension) F, P = 1mm increments

may become shorter. Please make sure that the nut motion range is F

greater than the full length of the nut.

56