Page 917 - MiSUMi FA Mechanical Components Economy Series

P. 917

19

Economy Series

Quality Assurance Metal Washers / Metal Collars

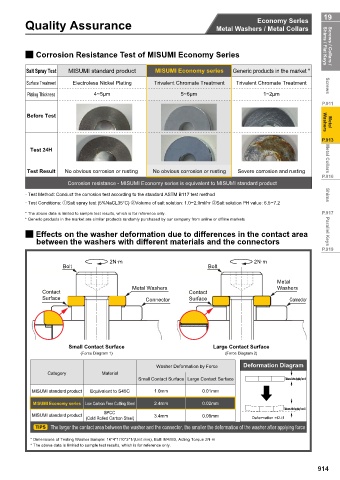

2 Corrosion Resistance Test of MISUMI Economy Series Shims / Flat Keys Screws / Collars /

Salt Spray Test MISUMI standard product MISUMI Economy series Generic products in the market *

Surface Treatment Electroless Nickel Plating Trivalent Chromate Treatment Trivalent Chromate Treatment Screws

Plating Thickness 4~5ȝm 5~6ȝm 1~2ȝm

P.911

Before Test Washers Metal

P.913

Test 24H Metal Collars

Test Result No obvious corrosion or rusting No obvious corrosion or rusting Severe corrosion and rusting

P.916

Corrosion resistance - MISUMI Economy series is equivalent to MISUMI standard product

· Test Method: Conduct the corrosion test according to the standard ASTM B117 test method Shims

· Test Conditions: Salt spray test (5%NaCL35°C) Volume of salt solution: 1.0~2.0ml/hr Salt solution PH value: 6.5~7.2

* The above data is limited to sample test results, which is for reference only. P.917

* Generic products in the market are similar products randomly purchased by our company from online or offline markets

2 Effects on the washer deformation due to differences in the contact area Parallel Keys

between the washers with different materials and the connectors

P.919

2N·m 2N·m

Bolt Bolt

Metal

Metal Washers Washers

Contact Contact

Surface Connector Surface Connector

Small Contact Surface Large Contact Surface

(Force Diagram 1) (Force Diagram 2)

Washer Deformation by Force Deformation Diagram

Category Material

Small Contact Surface Large Contact Surface ThicknessBeforeApplyingForcet1

MISUMI standard product Equivalent to S45C 1.0mm 0.01mm

MISUMI Economy series Low Carbon Free Cutting Steel 2.4mm 0.02mm

ThicknessAfterApplyingForcet2

SPCC

MISUMI standard product 3.4mm 0.08mm

(Cold Rolled Carbon Steel) Deformation =t2-t1

TIPS The larger the contact area between the washer and the connector, the smaller the deformation of the washer after applying force

* Dimensions of Testing Washer Sample: 16*4*1/10*3*1/(Unit mm), Bolt: M4/M3, Acting Torque 2N·m

* The above data is limited to sample test results, which is for reference only.

914