Page 976 - MiSUMi FA Mechanical Components Economy Series

P. 976

[Materials]

Varieties and Applications 1

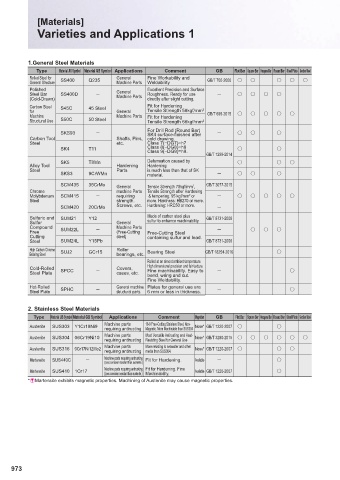

1.General Steel Materials

Type Material JIS Symbol Material GB Symbol Applications Comment GB Flat Bar Square Bar Hexagonal Bar Round Bar Steel Plate Section Steel

Rolled Steel for General Fine Workability and

General Structure SS400 Q235 Machine Parts Weldability GB/T 700-2006 k k k k k

Polished General Excellent Precision and Surface

Steel Bar SS400D Machine Parts Roughness. Ready for use k k k k

(Cold-Drawn) directly after slight cutting.

Carbon Steel S45C 45 Steel Fit for Hardening

for General Tensile Strength 58kgf/mm 2 GB/T 699-2015 k k k k k

Machine Machine Parts Fit for Hardening

Structural Use S50C 50 Steel Tensile Strength 66kgf/mm 2

For Drill Rod (Round Bar)

SKS93 SK4 surface-fi nished after k k k

Carbon Tool Shafts, Pins, cold drawing.

Steel etc. Class 7(−DG7)=h7

SK4 T11 Class 8(−DG8)=h8 k k

Class 9(−DG9)=h9.

GB/T 1299-2014

SK5 T8Mn Deformation caused by k k k

Alloy Tool Hardening Hardening

Steel Parts is much less than that of SK

SKS3 9CrWMn material. k k k

SCM435 35CrMo General Tensile Strength 70kgf/mm , GB/T 3077-2015

2

Chrome machine Parts Tensile Strength after Hardening

2

Molybdenum SCM415 requiring & tempering: 95 kgf/mm or k k k k k

Steel strength. more. Hardness: HB270 or more.

SCM420 20CrMo Screws, etc. Hardening: HRC50 or more.

Sulfuric and SUM21 Y12 Made of carbon steel plus GB/T 8731-2008

Sulfur General sulfur to enhance machinability.

Compound SUM22L Machine Parts k k k

Free (Free-Cutting Free-Cutting Steel

Cutting steel) containing sulfur and lead.

Steel SUM24L Y15Pb GB/T 8731-2008

High Carbon Chrome SUJ2 GCr15 Roller Bearing Steel GB/T 18254-2016 k

Bearing Steel bearings, etc.

Rolled at an almost ambient temperature.

High dimensional precision and fair texture.

Cold-Rolled Covers,

Steel Plate SPCC cases, etc. Fine machinability. Easy to k

bend, wring and cut.

Fine Weldability.

Hot-Rolled General machine Plates for general use are

Steel Plate SPHC structural parts. 6 mm or less in thickness. k

2. Stainless Steel Materials

Type Material JIS Symbol Material GB Symbol Applications Comment Magnetism GB Flat Bar Square Bar Hexagonal Bar Round Bar Steel Plate Section Steel

Machine parts 18-8 Free-Cutting Stainless Steel, Non-

Austenite SUS303 Y1Cr18Ni9 None* GB/T 1220-2007 k k

requiring antirusting Magnetic. More Machinable than SUS304

Machine parts Most Versatile Antirusting and Heat-

Austenite SUS304 06Cr19Ni10 None* GB/T 3280-2015 k k k k k k

requiring antirusting Resisting Steel for General Use

Machine parts More resisting to seawater and other

Austenite SUS316 0Cr17Ni12Mo2 None* GB/T 1220-2007 k k k

requiring antirusting media than SUS304.

Martensite SUS440C Machine parts requiring antirusting Fit for Hardening. Available k

(Less corrosion resistant than austenite.)

Machine parts requiring antirusting Fit for Hardening. Fine

Martensite SUS410 1Cr17 Available GB/T 1220-2007 k

(Less corrosion resistant than austenite.) Machinability.

*EMartensite exhibits magnetic properties. Machining of Austenite may cause magnetic properties.

973