Page 105 - IGUS Bearing

P. 105

iglidur G1 iglidur G1

®

®

+180 °C +180 °C

91MPa 91MPa

Bearing technology | Plain bearings | iglidur G1 Technical data

®

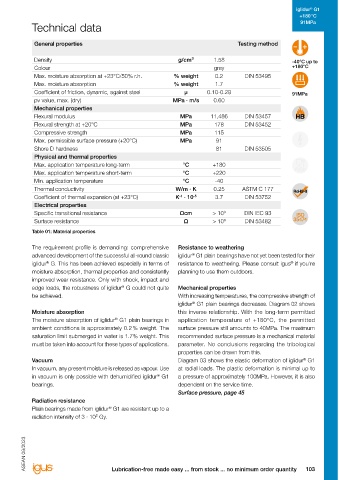

General properties Testing method

Density g/cm³ 1.58 -40°C up to

Ø Colour grey +180°C

4.0-50.0mm

Max. moisture absorption at +23°C/50% r.h. % weight 0.2 DIN 53495

Max. moisture absorption % weight 1.7

Coefficient of friction, dynamic, against steel µ 0.10-0.29 91MPa

pv value, max. (dry) MPa · m/s 0.60

Also available

as: Mechanical properties

More universal Flexural modulus MPa 11,486 DIN 53457

MPa

Flexural strength at +20°C

178

DIN 53452

The advanced development of iglidur G Compressive strength MPa 115

®

Bar stock, Max. permissible surface pressure (+20°C) MPa 91

round bar

Page 743 Shore D hardness 81 DIN 53505

The most successful plastic bearing in the world - iglidur G - improved all round: iglidur G1, the new

®

®

standard. Physical and thermal properties

● Double service life at high loads Max. application temperature long-term °C +180 FOOD

● Up to 4 times less wear at low loads Max. application temperature short-term °C +220

● Continuous operating temperatures up to +180°C Min. application temperature °C -40

Bar stock, ● Press-fit up to +120°C (iglidur G: up to +80°C) Thermal conductivity W/m · K 0.25 ASTM C 177

®

plate -1 -5

Page 773 ● Moisture absorption reduced by 50% Coefficient of thermal expansion (at +23°C) K · 10 3.7 DIN 53752

Electrical properties

Typical application areas Specific transitional resistance Ωcm > 10 9 DIN IEC 93

● Mechanical engineering Surface resistance Ω > 10 9 DIN 53482

● Automation Table 01: Material properties

tribo-tape liner ● Sports and leisure

Page 781 ● Automotive industry The requirement profile is demanding: comprehensive Resistance to weathering

®

● Mechatronics advanced development of the successful all-round classic iglidur G1 plain bearings have not yet been tested for their

iglidur G. This has been achieved especially in terms of resistance to weathering. Please consult igus if you're

®

®

moisture absorption, thermal properties and consistently planning to use them outdoors.

improved wear resistance. Only with shock, impact and

edge loads, the robustness of iglidur G could not quite Mechanical properties

®

Guide rings

Page 641 be achieved. With increasing temperatures, the compressive strength of

iglidur G1 plain bearings decreases. Diagram 02 shows

®

Descriptive technical specifications Moisture absorption this inverse relationship. With the long-term permitted

Wear resistance at +23°C – + The moisture absorption of iglidur G1 plain bearings in application temperature of +180°C, the permitted

®

ambient conditions is approximately 0.2 % weight. The surface pressure still amounts to 40MPa. The maximum

Wear resistance at +90°C – +

saturation limit submerged in water is 1.7% weight. This recommended surface pressure is a mechanical material

Two hole Wear resistance at +150°C – + must be taken into account for these types of applications. parameter. No conclusions regarding the tribological

flange

bearings properties can be drawn from this.

Page 667 Slide property – +

Vacuum Diagram 03 shows the elastic deformation of iglidur G1

®

Wear resistance under water – + In vacuum, any present moisture is released as vapour. Use at radial loads. The plastic deformation is minimal up to

in vacuum is only possible with dehumidified iglidur G1 a pressure of approximately 100MPa. However, it is also

®

Media resistance – +

bearings. dependent on the service time.

Moulded Resistant to edge pressures – + Surface pressure, page 45

special parts Radiation resistance

Page 696 Resistant to shock and impact loads – +

®

Plain bearings made from iglidur G1 are resistant up to a

Dirt resistance – + radiation intensity of 3 · 10² Gy.

®

igubal Online product finder Online service life calculation

spherical balls

Page 993 www.igus-asean.com/iglidur-finder www.igus-asean.com/iglidur-expert ASEAN 09/2023 ASEAN 09/2023

102 3D-CAD, finder and service life calculation ... www.igus-asean.com/G1 Lubrication-free made easy ... from stock ... no minimum order quantity 103