Page 505 - IGUS Bearing

P. 505

iglidur Q290 iglidur Q290

®

®

+140°C +140°C

55MPa 55MPa

Bearing technology | Plain bearings | iglidur Q290 Technical data

®

Permissible surface speeds Chemicals Resistance 100.0 0.20

Typical applications for iglidur Q290 plain bearings Alcohols + up to 0 10.0 0.15

®

are pivoting movements under medium to high loads Diluted acids 0 up to –

at comparatively low speeds. However, relatively high Diluted alkalines + 1.0 0.10

speeds are still attainable. The speeds shown in table 03 Fuels +

are threshold values for low bearing loads. They do not Greases, oils without additives + Surface pressure [MPa] 0.1 Coefficient of friction [µ] 0.05

provide any indication of the wear resistance under these Hydrocarbons +

parameters. Strong acids – 0.01 0.001 0.01 0.1 1.0 10.0 0.00

Surface speed, page 48 Strong alkalines + up to 0 1 10 25 40 55

Surface speed [m/s] Load [MPa]

All data given at room temperature [+20°C]

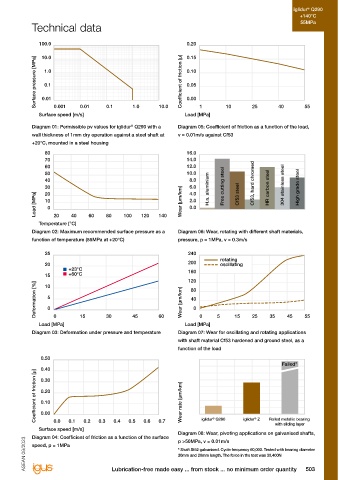

Temperature Diagram 01: Permissible pv values for iglidur Q290 with a Diagram 05: Coefficient of friction as a function of the load,

®

The long-term upper temperature limit of +140°C permits Table 02: Chemical resistance wall thickness of 1mm dry operation against a steel shaft at v = 0.01m/s against Cf53

Chemical table, page 1170

the broad use in applications typical for the agricultural, +20°C, mounted in a steel housing

utility vehicle or construction equipment sectors. For Rotating Oscillating linear 80 16.0

temperatures over +80°C an additional securing is Long-term m/s 0.8 0.6 1.0 70 14.0

required. Short-term m/s 2.0 1.4 2.0 60 12.0

Application temperatures, page 53 50 10.0

Additional securing, page 53 Table 03: Maximum surface speeds 40 8.0 Cf53, hard chromed

30 6.0 H.a. aluminium Free cutting steel HR carbon steel 304 stainless steel High grade steel

Dry Greases Oil Water 20 4.0 Cf53 steel

Friction and wear Coefficient of friction μ 0.14-0.26 0.09 0.04 0.04 10 Wear [µm/km] 2.0

Please note that a sliding surface with a rough surface Table 04: Coefficient of friction against steel (Ra = 1μm, Load [MPa] 0 0.0

finish will increase the friction. The coefficient of friction of 20 40 60 80 100 120 140

iglidur Q290 increases as the speed increases (diagram 50HRC) Temperature [°C]

®

04). In contrast, the coefficient of friction drops continually Housing Plain bearings Shaft Diagram 02: Maximum recommended surface pressure as a Diagram 06: Wear, rotating with different shaft materials,

with the radial load, as illustrated by diagram 05. Ø d1 [mm] H7 [mm] E10 [mm] h9 [mm] function of temperature (55MPa at +20°C) pressure, p = 1MPa, v = 0.3m/s

Coefficient of friction and surfaces, page 51 0-3 +0.000 +0.010 +0.014 +0.054 -0.025 +0.000

Wear resistance, page 54 25 240

> 3-6 +0.000 +0.012 +0.020 +0.068 -0.030 +0.000 rotating

20 200 oscillating

> 6-10 +0.000 +0.015 +0.025 +0.083 -0.036 +0.000

Shaft materials > 10-18 +0.000 +0.018 +0.032 +0.102 -0.043 +0.000 15 +23°C 160

+60°C

Generally, the use of hardened shafts is recommended > 18-30 +0.000 +0.021 +0.040 +0.124 -0.052 +0.000 120

for higher loads starting at approximately 10MPa. This > 30-50 +0.000 +0.025 +0.050 +0.150 -0.062 +0.000 10 80

is, however, often not the case in practice, especially in > 50-80 +0.000 +0.030 +0.060 +0.180 -0.074 +0.000 5 40

connection with corrosion-resistant coating methods. > 80-120 +0.000 +0.035 +0.072 +0.212 -0.087 +0.000 Deformation [%] Wear [µm/km]

Thus, the iglidur Q290 material has a lot of importance > 120-180 +0.000 +0.040 +0.085 +0.245 -0.100 +0.000 0 0

®

0

0

in such applications. Diagram 08 shows this very clearly in Load [MPa] 15 30 45 60 Load [MPa] 5 15 25 35 45 55

connection with galvanised shafts. The special suitability Table 05: Important tolerances for plain bearings according

for pivoting applications is shown in diagram 07. to ISO 3547-1 after press-fit Diagram 03: Deformation under pressure and temperature Diagram 07: Wear for oscillating and rotating applications

Shaft materials, page 56 with shaft material Cf53 hardened and ground steel, as a

function of the load

Installation tolerances 0.50 Failed*

iglidur Q290 plain bearings are standard bearings for 0.40

®

shafts with h tolerance (recommended minimum h9). The 0.30

bearings are designed for press-fit into a housing machined

to a H7 tolerance. After being assembled into a nominal Coefficient of friction [µ] 0.20

size housing, the inner diameter automatically adjusts to 0.10 Wear rate [µm/km]

the E10 tolerances. For particular dimensions the tolerance

differs depending on the wall thickness (please see product 0.00 iglidur Q290 iglidur Z Rolled metallic bearing

®

®

range table). 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 with sliding layer

Surface speed [m/s]

Testing methods, page 61 Diagram 04: Coefficient of friction as a function of the surface Diagram 08: Wear, pivoting applications on galvanised shafts,

ASEAN 09/2023 ASEAN 09/2023 speed, p = 1MPa * Shaft St52 galvanised. Cycle frequency 60,000. Tested with bearing diameter

p >50MPa, v = 0.01m/s

20mm and 20mm length. The force in the test was 30,400N

502 3D-CAD, finder and service life calculation ... www.igus-asean.com/Q290 Lubrication-free made easy ... from stock ... no minimum order quantity 503