Page 665 - IGUS Bearing

P. 665

®

®

iglidur iglidur

®

®

knife- iglidur knife edge rollers | Advantages iglidur knife edge rollers | Technical data knife-

edge- edge-

rollers rollers

Lubrication-free and precise deflection of conveyor belts

Material properties

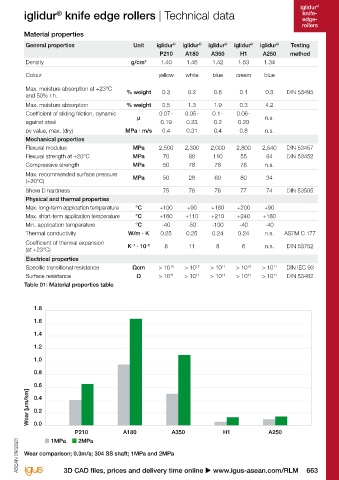

General properties Unit iglidur iglidur ® iglidur ® iglidur ® iglidur ® Testing

®

iglidur P210: Universal iglidur P210 A180 A350 H1 A250 method

®

®

Density g/cm 3 1.40 1.46 1.42 1.53 1.34

knife edge rollers

Tight belt deflection Colour yellow white blue cream blue

igus has developed its own knife-edge rollers Max. moisture absorption at +23°C

®

iglidur A180: to deflect conveyor belts in materials handling and 50% r.h. % weight 0.3 0.2 0.6 0.1 0.3 DIN 53495

®

FDA-compliant up to +90°C applications. The iglidur solution is characterised Max. moisture absorption % weight 0.5 1.3 1.9 0.3 4.2

®

by tight belt deflection and a low level of required Coefficient of sliding friction, dynamic 0.07 - 0.05 - 0.1 - 0.06 -

drive power. against steel µ 0.19 0.23 0.2 0.20 n.s.

Long service life pv value, max. (dry) MPa · m/s 0.4 0.31 0.4 0.8 n.s.

Mechanical properties

iglidur A350: Flexural modulus MPa 2,500 2,300 2,000 2,800 2,540 DIN 53457

®

FDA-compliant up to +180°C When to use it? Flexural strength at +20°C MPa 70 88 110 55 84 DIN 53452

● When a lubrication-free deflection of Compressive strength MPa 50 78 78 78 n.s.

conveyor belt is required Max. recommended surface pressure

Low drive power ● When a precise guiding is required (+20°C) MPa 50 28 60 80 34

● When a cost-effective and lightweight Shore D hardness 75 76 76 77 74 DIN 53505

iglidur H1: solution is required Physical and thermal properties

®

For higher Max. long-term application temperature °C +100 +90 +180 +200 +90

transport speeds Max. short-term application temperature °C +160 +110 +210 +240 +180

Min. application temperature °C -40 -50 -100 -40 -40

When not to use it? Thermal conductivity W/m · K 0.25 0.25 0.24 0.24 n.s. ASTM C 177

● In constant high speed belt Coefficient of thermal expansion

iglidur A250: ● When high forces are applied on the belts (at +23°C) K · 10 –5 8 11 8 6 n.s. DIN 53752

–1

®

FDA-compliant ● When a static knife edge is required Electrical properties

Specific transitional resistance Ωcm > 10 12 > 10 12 > 10 11 > 10 12 > 10 11 DIN IEC 93

Surface resistance Ω > 10 11 > 10 11 > 10 11 > 10 11 > 10 11 DIN 53482

Table 01: Material properties table

Available from stock 1.8

Detailed information about delivery time online.

1.6

Depending on material: 1.4

®

iglidur P210: -40°C up to +100°C 1.2

iglidur A180: -50°C up to +90°C

®

®

iglidur A350: -100°C up to +180°C 1.0

iglidur H1: -40°C up to +200°C

®

0.8

4 materials 0.6

Wear [µm/km] 0.2

Ø 9 - 20mm 0.4

More dimensions upon request

0.0

P210 A180 A350 H1 A250

1MPa 2MPa

ASEAN 09/2023 ASEAN 09/2023 Wear comparison; 0.3m/s; 304 SS shaft; 1MPa and 2MPa

662 Online tools and more information u www.igus-asean.com/RLM 3D CAD files, prices and delivery time online u www.igus-asean.com/RLM 663