Page 785 - IGUS Bearing

P. 785

iglidur tribo-tape | Advantages iglidur tribo-tape | Technical data tribo-tape

®

iglidur

®

®

Versatile: iglidur tribo-tape

®

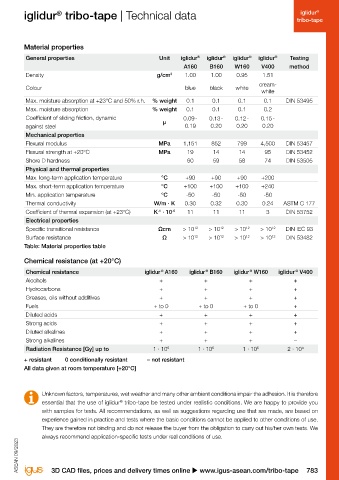

Easy-to-fit protection General properties Unit iglidur ® iglidur ® iglidur ® iglidur ® Testing

®

Material: iglidur A160 Material properties

● Low coefficient of friction for all surfaces: A160 B160 W160 V400 method

● Wear resistance: ++ Density g/cm 3 1.00 1.00 0.95 1.51

®

● Up to +90°C iglidur tribo-tape Colour blue black white cream-

u Page 786 white

igus tribo-tape is designed for lining areas of wear Max. moisture absorption at +23°C and 50% r.h. % weight 0.1 0.1 0.1 0.1 DIN 53495

®

and where frequent maintenance is required, an Max. moisture absorption % weight 0.1 0.1 0.1 0.2

example is for machine beds etc. At just 0.5mm Coefficient of sliding friction, dynamic µ 0.09 - 0.13 - 0.12 - 0.15 -

thick (0.71mm including the adhesive back), the against steel 0.19 0.20 0.20 0.20

space requirement is extremely low. The ease of Mechanical properties

use (the tape can simply be cut using scissors) Flexural modulus MPa 1,151 852 799 4,500 DIN 53457

Material: iglidur B160 and optional self-adhesive back open up almost Flexural strength at +20°C MPa 19 14 14 95 DIN 53452

®

endless possibilities for the product's use. Shore D hardness 60 59 58 74 DIN 53505

● For use in visible areas ● Lubrication and maintenance-free Physical and thermal properties

● Wear resistance: ++++ ● Easy to cut Max. long-term application temperature °C +90 +90 +90 +200

● Up to +90°C ● For compact areas Max. short-term application temperature °C +100 +100 +100 +240

u Page 787 ● With or without self-adhesive back Min. application temperature °C -50 -50 -50 -50

● Standard widths from stock Thermal conductivity W/m · K 0.30 0.32 0.30 0.24 ASTM C 177

-1

● Individual required widths in continuous range Coefficient of thermal expansion (at +23°C) K · 10 -5 11 11 11 3 DIN 53752

from 10-500mm Electrical properties

Specific transitional resistance Ωcm > 10 12 > 10 12 > 10 12 > 10 12 DIN IEC 93

Surface resistance Ω > 10 12 > 10 12 > 10 12 > 10 12 DIN 53482

Table: Material properties table

Chemical resistance (at +20°C)

®

Material: iglidur W160

®

®

®

®

Available from stock Chemical resistance iglidur A160 iglidur B160 iglidur W160 iglidur V400

● White and UV-stabilised Detailed information about delivery time online. Alcohols + + + +

● Wear resistance: +++ Hydrocarbons + + + +

● Up to +90°C Operation temperatures: Greases, oils without additives + + + +

®

u Page 788 iglidur A160: -50°C up to +90°C Fuels + to 0 + to 0 + to 0 +

®

iglidur B160: -50°C up to +90°C Diluted acids + + + +

®

iglidur W160: -50°C up to +90°C Strong acids + + + +

®

iglidur V400: -50°C up to +200°C Diluted alkalines + + + +

Differing temperatures with adhesive back Strong alkalines + + + –

(see product page) Radiation Resistance [Gy] up to 1 · 10 5 1 · 10 5 1 · 10 5 2 · 10 4

+ resistant 0 conditionally resistant – not resistant

Material: iglidur V400 Product film All data given at room temperature [+20°C]

®

u www.igus-asean.com/tape-film

● High media resistance

● Wear resistance: +++++ Cutting service Unknown factors, temperatures, wet weather and many other ambient conditions impair the adhesion. It is therefore

®

● Up to +200°C (with Whether as a specially tailored by-the-metre essential that the use of iglidur tribo-tape be tested under realistic conditions. We are happy to provide you

adhesive back, see product or freely designed pre-cut parts: We with samples for tests. All recommendations, as well as suggestions regarding use that are made, are based on

product page) produce your required product in required width experience gained in practice and tests where the basic conditions cannot be applied to other conditions of use.

u Page 789 from our iglidur tribo-tape. Please contact us. They are therefore not binding and do not release the buyer from the obligation to carry out his/her own tests. We

®

u www.igus-asean.com/tape-cut-to-size always recommend application-specific tests under real conditions of use.

ASEAN 09/2023 ASEAN 09/2023

782 Online tools and more information u www.igus-asean.com/tribo-tape 3D CAD files, prices and delivery times online u www.igus-asean.com/tribo-tape 783