Page 263 - IGUS Linear

P. 263

drylin R shaft guides | igus testing method drylin R shaft guides | igus testing method

®

®

®

®

igus testing method for measuring the tolerance of drylin linear plain bearings

®

®

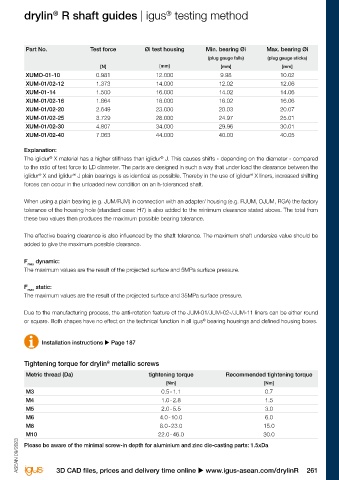

To ensure the correct function of a drylin R linear plain bearing, it is necessary to use the bearing with a defined minimum Part No. Test force Øi test housing Min. bearing Øi Max. bearing Øi

®

oversize (bearing clearance). The quality control of this part is carried out with a plug gauge test. For this purpose, specific force (plug gauge falls) (plug gauge sticks)

is defined with which the plug gauge is loaded when the plain bearing is tested. [N] [mm] [mm] [mm]

XUMO-01-10 0.981 12.000 9.98 10.02

Part No. Test force Øi test housing Min. bearing Øi Max. bearing Øi XUM-01/02-12 1.373 14.000 12.02 12.06

(plug gauge falls) (plug gauge sticks) XUM-01-14 1.500 16.000 14.02 14.06

[N] [mm] [mm] [mm] XUM-01/02-16 1.864 18.000 16.02 16.06

J / J200 / E7 / A180 / A160UM-01/02-10 0.981 12.000 10.030 10.070 XUM-01/02-20 2.649 23.000 20.03 20.07

J / J200 / E7 / A180 / A160UM-01/02-12 1.373 14.000 12.030 12.070 XUM-01/02-25 3.729 28.000 24.97 25.01

J / J200 / E7 / A180 / A160UM-01/02-16 1.864 18.000 16.030 16.070 XUM-01/02-30 4.807 34.000 29.96 30.01

J / J200 / E7 / A180 / A160UM-01/02-20 2.649 23.000 20.030 20.070 XUM-01/02-40 7.063 44.000 40.00 40.05

J / J200 / E7 / A180 / A160UM-01/02-25 3.729 28.000 25.030 25.070

J / J200 / E7 / A180 / A160UM-01/02-30 4.807 34.000 30.040 30.090 Explanation:

®

®

J / J200 / E7 / A180 / A160UM-01/02-40 7.063 44.000 40.040 40.090 The iglidur X material has a higher stiffness than iglidur J. This causes shifts - depending on the diameter - compared

J / J200 / E7 / A180 / A160UM-01/02-50 9.810 55.000 50.050 50.150 to the ratio of test force to LD diameter. The parts are designed in such a way that under load the clearance between the

®

®

®

J / J200 / E7UM-01/02-60 13.047 65.000 60.050 60.150 iglidur X and iglidur J plain bearings is as identical as possible. Thereby in the use of iglidur X liners, increased shifting

[N] [Imperial dimension] [Imperial dimension] [Imperial dimension] forces can occur in the unloaded new condition on an h-toleranced shaft.

JUI-01-06 0.981 0.4684 0.3768 0.3776

JUI-01-08 1.373 0.5934 0.5016 0.5024 When using a plain bearing (e.g. JUM/RJM) in connection with an adapter/ housing (e.g. RJUM, OJUM, RGA) the factory

JUI-01-10 1.864 0.7184 0.6268 0.6276 tolerance of the housing hole (standard case: H7) is also added to the minimum clearance stated above. The total from

JUI-01-12 2.649 0.8747 0.7516 0.7524 these two values then produces the maximum possible bearing tolerance.

JUI-01-16 3.729 1.1247 1.0016 1.0024

JUI-01-20 4.807 1.4058 1.2520 1.2531 The effective bearing clearance is also influenced by the shaft tolerance. The maximum shaft undersize value should be

JUI-01-24 7.063 1.6558 1.5020 1.5031 added to give the maximum possible clearance.

JUI-01-32 9.810 2.1870 2.0024 2.0039

[N] [mm] [mm] [mm] F max dynamic:

RJM / RJMP / RJ4JP-01-08 – 16.000 8.025 8.061 The maximum values are the result of the projected surface and 5MPa surface pressure.

RJM / RJMP / RJ4JP-01-10 – 19.000 10.025 10.061

RJM / RJMP / RJ4JP-01-12 – 22.000 12.032 12.075 F max static:

RJM / RJMP / RJ4JP-01-16 – 26.000 16.032 16.075 The maximum values are the result of the projected surface and 35MPa surface pressure.

RJM / RJMP / RJ4JP-01-20 – 32.000 20.040 20.092

RJM / RJMP / RJ4JP-01-25 – 40.000 25.040 25.092 Due to the manufacturing process, the anti-rotation feature of the JUM-01/JUM-02-/JUM-11 liners can be either round

®

RJM / RJMP / RJ4JP-01-30 – 47.000 30.040 30.092 or square. Both shapes have no effect on the technical function in all igus bearing housings and defined housing bores.

RJM / RJMP-01-40 – 62.000 40.050 40.112

[N] [Imperial dimension] [Imperial dimension] [Imperial dimension]

Installation instructions u Page 187

RJI-01-06 0.981 0.6250 0.3762 0.3776

RJI-01-08 1.373 0.8750 0.5013 0.5030

®

RJI-01-10 1.864 1.1250 0.6265 0.6282 Tightening torque for drylin metallic screws

RJI-01-12 2.649 1.2500 0.7516 0.7536 Metric thread (Da) tightening torque Recommended tightening torque

RJI-01-16 3.729 1.5625 1.0035 1.0056 [Nm] [Nm]

RJI-01-20 4.807 2.0000 1.2520 1.2544 M3 0.5 - 1.1 0.7

RJI-01-24 7.063 2.3750 1.5020 1.5044 M4 1.0 - 2.8 1.5

RJI-01-32 9.810 3.0000 2.0024 2.0053 M5 2.0 - 5.5 3.0

[N] [mm] [mm] [mm] M6 4.0 - 10.0 6.0

RJ260(U)M-02-12 – 19.000 12.032 12.084 M8 8.0 - 23.0 15.0

RJ260(U)M-02-16 – 24.000 16.032 16.084 M10 22.0 - 46.0 30.0

RJ260(U)M-02-20 – 28.000 20.040 20.100 Please be aware of the minimal screw-in depth for aluminium and zinc die-casting parts: 1.5xDa

RJ260(U)M-02-25 – 35.000 25.040 25.100 ASEAN 09/2023 ASEAN 09/2023

260 Online tools and more information u www.igus-asean.com/drylinR 3D CAD files, prices and delivery time online u www.igus-asean.com/drylinR 261