Page 44 - IGUS Linear

P. 44

drylin linear technology | Slides instead of rolling!

®

Use in dirt

Even the application under coarse dirt and sand is possible.

Particles are repelled from the contact surface by the

movement itself. Seals can be dispensed with due to the

dry operation. Dust and dirt cannot stick to grease or oil.

Surfaces

Hard-anodised surfaces are characterised by good wear

properties, high chemical resistance and a high degree of

hardness. It is a technical and not a decorative surface.

Colour alteration and slight cracking may occur, but do

not influence the resistance, the corrosion behaviour or

the sliding properties.

Eloxal stands for the electrolytic oxidation of aluminium.

This gives the CA rail profiles a silver/colourless surface

that is resistant to corrosion and wear. A lot of aluminium

profiles are also available as black anodised (AR anti-reflect) Lubrication-free and resistant to dust and dirt

versions. Both variants (CA/AR) are suitable for applications

that require consistent colouring.

Cutting surfaces and machined surfaces are uncoated.

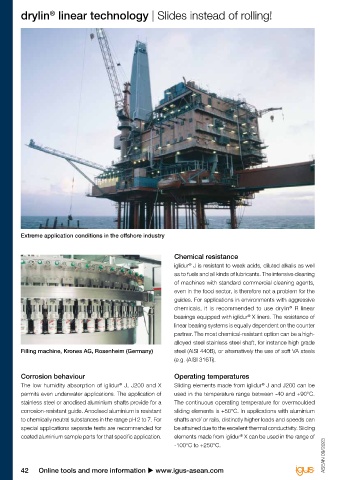

Extreme application conditions in the offshore industry

Chemical resistance

iglidur J is resistant to weak acids, diluted alkalis as well

®

as to fuels and all kinds of lubricants. The intensive cleaning

of machines with standard commercial cleaning agents,

even in the food sector, is therefore not a problem for the

guides. For applications in environments with aggressive

chemicals, it is recommended to use drylin R linear

®

bearings equipped with iglidur X liners. The resistance of

®

linear bearing systems is equally dependent on the counter

partner. The most chemical-resistant option can be a high-

alloyed steel stainless steel shaft, for instance high grade

Filling machine, Krones AG, Rosenheim (Germany) steel (AISI 440B), or alternatively the use of soft VA steels

(e.g. (AISI 316Ti).

Corrosion behaviour Operating temperatures

The low humidity absorption of iglidur J, J200 and X Sliding elements made from iglidur J and J200 can be

®

®

permits even underwater applications. The application of used in the temperature range between -40 and +90°C.

stainless steel or anodised aluminium shafts provide for a The continuous operating temperature for overmoulded

corrosion-resistant guide. Anodised aluminium is resistant sliding elements is +50°C. In applications with aluminium

to chemically neutral substances in the range pH 2 to 7. For shafts and/ or rails, distinctly higher loads and speeds can

special applications separate tests are recommended for be attained due to the excellent thermal conductivity. Sliding

coated aluminium sample parts for that specific application. elements made from iglidur X can be used in the range of

®

ASEAN 09/2023 ASEAN 09/2023

-100°C to +250°C. The iglidur X material in heavy-duty use under high temperatures in foundries

®

42 Online tools and more information u www.igus-asean.com 3D CAD files, prices and delivery time online u www.igus-asean.com 43