Page 14 - Bosch Modernisation of Boiler Systems

P. 14

14 | Modernisation of boiler systems

Reference: Oettinger Brewery

Oettinger Brewery has modernised its steam generation at its production site North in Oettingen

(Bavaria). This has enabled the brewery to save year by year over 650 tons of CO 2 emissions and

approximately 20 % of its energy costs for process heat.

The steam supply consists of two Loos (today Bosch) boiler efficiency by around 6 % and reduces the fuel usage

3-pass boilers produced in 1991 and 1993. In the as well as helping to keep emissions low.

context of a modernisation program, the existing

steam generating systems have been brought to the The replacement of the existing combi-burners with

latest standards of efficiency and eco-friendliness. The modern, modulating natural gas burners resulted in a fur-

measures comprised the integration of: ther increase in efficiency. Thanks to the use of a burner fan

▶ flue gas heat exchangers (not present on the control, the motor speed is reduced depending on the

existing boilers) boiler’s output. The electrical power consumption in the

▶ speed-controlled burner fans partial load range is therefore considerably lower – and at

▶ combustion control with O 2 probe the same time there is also a significant reduction in the

▶ boiler and system controls including sequence sound level. Even the oxygen content in the flue gas is now

control for the efficient and optimised operation of also continually measured. If this is too high, making com-

the multi-boiler system bustion ineffective, the amount of combustion air is redu-

ced. This optimises the efficiency of the burner system and

The retrofitted economizers reduce the flue gas tempe- reduces CO2 emissions as well as energy costs.

rature from approximately 230 °C to almost 115 °C

through preheating the feed water. This increases the

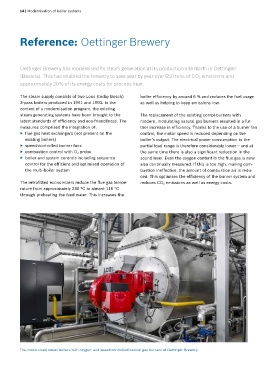

The modernised steam boilers with oxygen- and speed-controlled natural gas burners at Oettinger Brewery.