Page 263 - ASEAN Chainflex Catalogue 2023

P. 263

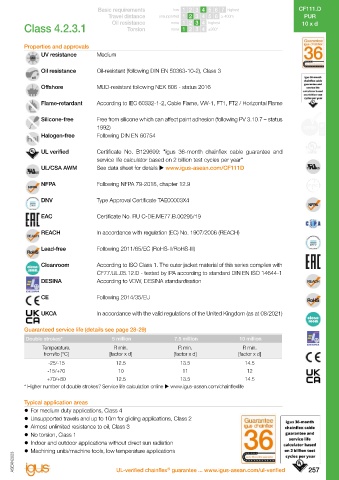

CF111.D PVC iguPUR PUR TPE Basic requirements low 1 2 3 4 5 6 7 highest CF111.D

PUR New Travel distance unsupported 1 2 3 4 5 6 ≥ 400m PUR

10 x d ® Oil resistance none 1 2 3 4 highest 10 x d

Measuring system cable | PUR | chainflex CF111.D Class 4.2.3.1 Torsion none 1 2 3 4 ±360°

10 million 10 x d 10m Properties and approvals Medium

UV resistance

Double strokes guaranteed Bend radius, e-chain ® Travel distance, e-chain ®

Oil resistance Oil-resistant (following DIN EN 50363-10-2), Class 3

z For medium duty applications

z PUR outer jacket Offshore MUD-resistant following NEK 606 - status 2016

z Shielded

z Oil-resistant and coolant-resistant Flame-retardant According to IEC 60332-1-2, Cable Flame, VW-1, FT1, FT2 / Horizontal Flame

z Flame-retardant

z PVC and halogen-free Silicone-free Free from silicone which can affect paint adhesion (following PV 3.10.7 – status

z Notch-resistant 1992)

z Hydrolysis and microbe-resistant Halogen-free Following DIN EN 60754

Dynamic information UL verified Certificate No. B129699: "igus 36-month chainflex cable guarantee and

Bend radius e-chain linear minimum 10 x d service life calculator based on 2 billion test cycles per year"

®

flexible minimum 8 x d UL/CSA AWM See data sheet for details www.igus-asean.com/CF111D

fixed minimum 5 x d

®

Temperature e-chain linear -25°C up to +80°C NFPA Following NFPA 79-2018, chapter 12.9

flexible -40°C up to +80°C (following DIN EN 60811-504)

fixed -50°C up to +80°C (following DIN EN 50305) DNV Type Approval Certificate TAE00003X4

v max. unsupported 5m/s

gliding 3m/s EAC Certificate No. RU C-DE.ME77.B.00295/19

a max. 30m/s²

REACH In accordance with regulation (EC) No. 1907/2006 (REACH)

Travel distance Unsupported travels and up to 10m for gliding applications, Class 2

Lead-free Following 2011/65/EC (RoHS-II/RoHS-III)

Cable structure

Conductor Very finely stranded special conductors of particularly bending resistant design Cleanroom According to ISO Class 1. The outer jacket material of this series complies with

made of tinned copper wires. CF77.UL.05.12.D - tested by IPA according to standard DIN EN ISO 14644-1

Core insulation Mechanically high-quality TPE mixture. DESINA According to VDW, DESINA standardisation

Core structure According to measuring system specification. CE Following 2014/35/EU

Core identification According to measuring system specification. UKCA In accordance with the valid regulations of the United Kingdom (as at 08/2021)

Product range table

Element shield Extremely bending-resistant, tinned copper cover. Guaranteed service life (details see page 28-29)

Coverage approx. 90% optical Double strokes* 5 million 7.5 million 10 million

®

Element shield TPE mixture on pair shielding adapted to suit the requirements in e-chains . Temperature, R min. R min. R min.

from/to [°C] [factor x d] [factor x d] [factor x d]

Intermediate layer Foil taping over the outer layer. -25/-15 12.5 13.5 14.5

-15/+70 10 11 12

Overall shield Bending-resistant braiding made of tinned copper wires. +70/+80 12.5 13.5 14.5

Coverage linear approx. 55%, optical approx. 80% * Higher number of double strokes? Service life calculation online www.igus-asean.com/chainflexlife

Outer jacket Low-adhesion, halogen-free, highly abrasion resistant PUR mixture, adapted

to suit the requirements in e-chains (following DIN EN 50363-10-2) Typical application areas

®

Colour: Yellow-green (similar to RAL 6018) z For medium duty applications, Class 4

z Unsupported travels and up to 10m for gliding applications, Class 2

Almost unlimited resistance to oil, Class 3

Example image Nominal voltage 50V z No torsion, Class 1

z

Electrical information

300V (following UL)

Indoor and outdoor applications without direct sun radiation

z

500V

Testing voltage

ASEAN2023 ASEAN2023 z Machining units/machine tools, low temperature applications

256 36-month guarantee ... more than 1,350 cable types from stock ... no cutting charges UL-verified chainflex guarantee ... www.igus-asean.com/ul-verified 257

®