Page 415 - ASEAN Chainflex Catalogue 2023

P. 415

CFROBOT8 PVC iguPUR PUR TPE Basic requirements low 1 2 3 4 5 6 7 highest CFROBOT8

PUR Travel distance unsupported 1 2 3 4 5 6 ≥ 400m PUR

±180°/m ® Oil resistance none 1 2 3 4 highest ±180°/m

Bus cable | PUR | chainflex CFROBOT8 Class 6.1.3.3 Torsion none 1 2 3 4 ±360°

Example image

Number of cores and conductor Outer diameter Copper Characteristic wave

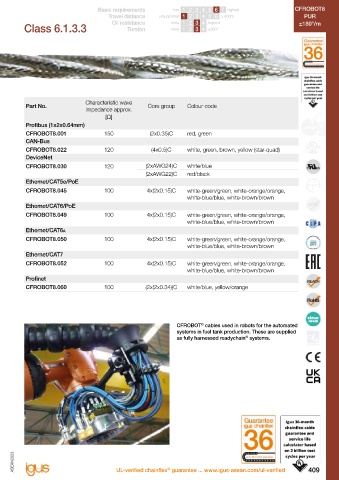

Part No. Weight Part No. Core group Colour code

nominal cross section (d) max. index impedance approx.

[mm²] [mm] [kg/km] [kg/km] [Ω]

Profibus (1x2x0.64mm) Profibus (1x2x0.64mm)

CFROBOT8.001 (2x0.35)C 8.0 28 63 CFROBOT8.001 150 (2x0.35)C red, green

CAN-Bus CAN-Bus

CFROBOT8.022 (4x0.5)C 7.5 41 78 CFROBOT8.022 120 (4x0.5)C white, green, brown, yellow (star-quad)

DeviceNet DeviceNet

CFROBOT8.030 (2xAWG24)C 9.5 31 77 CFROBOT8.030 120 (2xAWG24)C white/blue

+(2xAWG22)C (2xAWG22)C red/black

Ethernet/CAT5e/PoE Ethernet/CAT5e/PoE

CFROBOT8.045 4x(2x0.15)C 9.5 48 96 CFROBOT8.045 100 4x(2x0.15)C white-green/green, white-orange/orange,

white-blue/blue, white-brown/brown

Ethernet/CAT6/PoE Ethernet/CAT6/PoE

CFROBOT8.049 4x(2x0.15)C 9.5 48 96 CFROBOT8.049 100 4x(2x0.15)C white-green/green, white-orange/orange,

white-blue/blue, white-brown/brown

Ethernet/CAT6A Ethernet/CAT6A

CFROBOT8.050 4x(2x0.15)C 10.5 51 134 CFROBOT8.050 100 4x(2x0.15)C white-green/green, white-orange/orange,

white-blue/blue, white-brown/brown

Ethernet/CAT7 Ethernet/CAT7

CFROBOT8.052 4x(2x0.15)C 10.5 51 134 CFROBOT8.052 100 4x(2x0.15)C white-green/green, white-orange/orange,

white-blue/blue, white-brown/brown

Profinet Profinet

CFROBOT8.060 (2x(2x0.34))C 8.5 34 74 CFROBOT8.060 100 (2x(2x0.34))C white/blue, yellow/orange

Note: The given outer diameters are maximum values and may tend toward lower tolerance limits.

G = with green-yellow earth core x = without earth core

CFROBOT cables used in robots for the automated

®

Cables available in the chainflex CASE systems in fuel tank production. These are supplied

®

®

Simple savings on delivery, storage space and re-ordering with as fully harnessed readychain systems.

the chainflex CASE - ship'n store by igus .

®

®

More on this on page 24/25 and online: www.igus-asean.com/cf-case

Technical note on bus cables

chainflex bus cables have been specially developed and tested for continuously moving use in e-chains . Depending on the

®

®

material used for the outer jacket and on the underlying construction principle, the bus cables are designed for different mechanical

requirements and resistance to diverse media.

The cables have been electrically designed in such a way that, on the one hand, the electrical requirements of the respective bus

specification are reliably met and, on the other, that greater value is placed on a high degree of EMC reliability.

It is also ensured that the electrical values remain stable over the long term in spite of permanent movement.

The overall quality of transmission in a complete bus communication system, however, is not solely dependent on the cable used.

What is also essential is that all components (electronic parts, connecting system and cable) are precisely matched to each other

and that the maximum transmission lengths, which are dependent on the respective system, are adhered to with regard to the data

transmission rates needed. A cable is thus not solely responsible for the reliable transmission of signals.

®

igus advises you when you are designing your bus system to take all these factors into account and, with extensive tests, helps you

to ensure the process reliability of your system from the very beginning.

ASEAN2023 ASEAN2023

408 36-month guarantee ... more than 1,350 cable types from stock ... no cutting charges UL-verified chainflex guarantee ... www.igus-asean.com/ul-verified 409

®