Page 933 - ASEAN Chainflex Catalogue 2023

P. 933

chainflex … ... lasts or your money back!

®

The tricks and ingenious features of... ...the chainflex design and why we feel so confident about this design

®

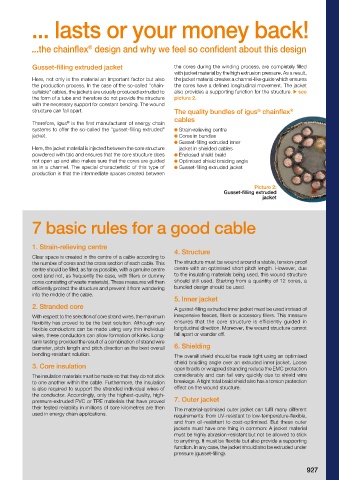

The production of the shield itself is very time-consuming Gusset-filling extruded jacket the cores during the winding process, are completely filled

and cost-intensive and may have been the reason for the with jacket material by the high extrusion pressure. As a result,

use of open braid shields or even simple wire wrappings. Here, not only is the material an important factor but also the jacket material creates a channel-like guide which ensures

The disadvantages are obvious: open shields only possess the production process. In the case of the so-called "chain- the cores have a defined longitudinal movement. The jacket

a limited shielding effect when moving - motion reduces this suitable" cables, the jackets are usually produced extruded to also provides a supporting function for the structure. see

effect even further. The type of shield is therefore an important the form of a tube and therefore do not provide the structure picture 2.

point that is not even mentioned in some catalogues. with the necessary support for constant bending. The wound

structure can fall apart. The quality bundles of igus chainflex

®

®

In its approx. 70% linear and approx. 90% optical coverage cables

cables, igus eliminates these weaknesses by means of an Therefore, igus is the first manufacturer of energy chain

®

®

optimised internal structure. In virtually all shielded chainflex systems to offer the so-called the "gusset-filling extruded" Strain-relieving centre

®

cables, a gusset-filling extruded inner jacket over the core jacket. Cores in bundles

structure is used. This "second jacket" fulfils two tasks: Gusset-filling extruded inner

Here, the jacket material is injected between the core structure jacket in shielded cables

It holds the core structure together and guides the powdered with talc and ensures that the core structure does Enclosed shield braid

individual cores as in a channel. not open up and also makes sure that the cores are guided Optimised shield braiding angle

It serves as a firm, round base for a very tight-fitting as in a channel. The special characteristic of this type of Gusset-filling extruded jacket

shield. see picture 1. production is that the intermediate spaces created between

Picture 2:

Shield wire breakage - and how this can Gusset-filling extruded

be prevented jacket

Even during the production of the shield, there are many things

that can be done correctly - or incorrectly. Here, an important

parameter is the braiding angle. 7 basic rules for a good cable

In the case of "chain-suitable" cables, tensile load on the

shield wires in the outer radius of the cable must be taken

into account. If an unfavourable braiding angle is used, the

tensile load increases even further and shield wire breakage 1. Strain-relieving centre

is the result. The consequences range from reduced shielding Clear space is created in the centre of a cable according to 4. Structure

effects right up to short circuits whenever the sharp wire ends the number of cores and the cross section of each cable. This The structure must be wound around a stable, tension-proof

penetrate through the fleeces or foils into the cores. Here is centre should be filled, as far as possible, with a genuine centre centre with an optimised short pitch length. However, due

a useful tip: If, after the insulation has been stripped off, the cord (and not, as frequently the case, with fillers or dummy to the insulating materials being used, this wound structure

shield can be easily pushed back over the jacket, the shield cores consisting of waste materials). These measures will then should still used. Starting from a quantity of 12 cores, a

is then usually unsuitable for use in moving energy supply efficiently protect the structure and prevent it from wandering bundled design should be used.

systems! This is a problem that igus has now solved with its into the middle of the cable.

®

novel approach: 5. Inner jacket

2. Stranded core

The shield braiding angle determined in long-term tests A gusset-filling extruded inner jacket must be used instead of

efficiently neutralises the tensile strengths and is therefore With respect to the selection of core strand wires, the maximum inexpensive fleeces, fillers or accessory fillers. This measure

Jac ket b reak age of highly suitable for energy chains. flexibility has proved to be the best solution. Although very ensures that the core structure is efficiently guided in

(36x0.14mm ) after only Due to the stable inner jacket, the shield cannot become flexible conductors can be made using very thin individual longitudinal direction. Moreover, the wound structure cannot

2

900,000 double strokes with uncontrolled. wires, these conductors can allow formation of kinks. Long- fall apart or wander off.

a bend radius factor of 7.8 x d term testing provided the result of a combination of strand wire

The shield itself has a torsion protection effect on the

wound structure. diameter, pitch length and pitch direction as the best overall 6. Shielding

bending-resistant solution. The overall shield should be made tight using an optimised

shield braiding angle over an extruded inner jacket. Loose

3. Core insulation open braids or wrapped stranding reduce the EMC protection

Jacket abrasion/jacket breakage The insulation materials must be made so that they do not stick considerably and can fail very quickly due to shield wire

to one another within the cable. Furthermore, the insulation breakage. A tight total braid shield also has a torsion protection

Whilst defects in the internal structure are hardly detectable is also required to support the stranded individual wires of effect on the wound structure.

on the outside, jacket problems are immediately obvious. the conductor. Accordingly, only the highest-quality, high-

The jacket is the first protection for the complicated internal pressure-extruded PVC or TPE materials that have proved 7. Outer jacket

structure. This is why broken, worn and swollen jackets are their tested reliability in millions of core kilometres are then

a serious quality defect. To prevent this problem, the igus used in energy chain applications. The material-optimised outer jacket can fulfil many different

®

customer can select from 7 jacket materials to adapt their requirements: from UV-resistant to low-temperature-flexible,

energy chain cables to suit the conditions of the respective and from oil-resistant to cost-optimised. But these outer

Picture 1: Optimised shield braiding angle over environment. jackets must have one thing in common: A jacket material

gusset-filling extruded inner jacket must be highly abrasion-resistant but not be allowed to stick

to anything. It must be flexible but also provide a supporting

function. In any case, the jacket should also be extruded under

pressure (gusset-filling).

927

926 927