Page 940 - ASEAN Chainflex Catalogue 2023

P. 940

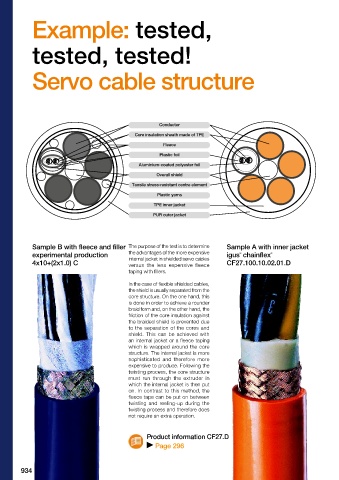

Example: tested, Comparison between the igus

®

solution with the gusset-filling

tested, tested! internal jacket and the fleece

version with fillers

Servo cable structure Here, the servo cables are highly flexible motor cables with

a complete copper shield and an integrated, shielded pair

of control cores. This cable type was selected due to the

fact that the structure is not axisymmetric due to the different

core cross sections, and therefore emphasises the bending

behaviours of the different production methods.

Sample A: CF27.100.10.02.01.D (igus GmbH)

®

(4x10mm ) + (2x1.0mm )

2

2

Conductor

Sample B: experimental

Core insulation sheath made of TPE (4x10mm ) + (2x1.0mm )

2

2

Fleece

Both cables are provided with identical nominal cross sections

Plastic foil and insulation materials. Cable A is equipped with an internal

lll lll

lll lll llll llll jacket and cable B with a fleece taping and fillers.

llll

llll

llll llll llll llll

llll

llll

llll llll llll llll ll

ll

llll ll llll ll Aluminium-coated polyester foil

The experimental production (sample B) shows the formation

Overall shield

of a corkscrew after just 145,000 double strokes. In the case

Tensile stress-resistant centre element of a cable, the so-called corkscrew refers to the wave-shaped

deformation like that seen in the picture of sample B.

Plastic yarns

TPE inner jacket In the case of cable A, the internal jacket fills up the gussets

and a round braided structure is created as a result, cable B

PUR outer jacket requires fillers in the gussets. Like the core, the fillers are made

of filbrated polyethylene. They are easy to compress and are

therefore don‘t offer much support. By contrast, the internal

jacket, which is made of TPE, and the cable A centre element

hold the cores in a defined position. The cores of cable B are

Sample B with fleece and filler The purpose of the test is to determine Sample A with inner jacket able to move about with no resistance. During the bending

experimental production the advantages of the more expensive igus chainflex ® process, cores can detach themselves from the braid structure

®

internal jacket in shielded servo cables

4x10+(2x1.0) C versus the less expensive fleece CF27.100.10.02.01.D and shift into the inner bend radius or outer radius. This results

in the corkscrew-type deformations that repeat themselves

taping with fillers. periodically along the length.

In the case of flexible shielded cables,

the shield is usually separated from the Assessment

core structure. On the one hand, this 5,000,000 5,000,000

is done in order to achieve a rounder Despite the extremely low bending factor of 4.76, no signs of

braid form and, on the other hand, the wear can be detected in sample A (CF27.100.10.02.01.D) even 4,000,000

friction of the core insulation against after 5 million double strokes. Sample B, on the other hand, 3,000,000

the braided shield is prevented due with its fillers and fleece taping, succumbs to a corkscrew 2,000,000

to the separation of the cores and formation after just 145,000 double strokes. Therefore, 1,000,000

shield. This can be achieved with the result justifies the extra expenditure of the cable Number of double strokes 750,000

an internal jacket or a fleece taping with the gusset-filling internal jacket. 500,000

which is wrapped around the core 250,000 145,000

structure. The internal jacket is more 100,000

sophisticated and therefore more 50,000

expensive to produce. Following the 0

twisting process, the core structure Sample B Sample A

must run through the extruder in

which the internal jacket is then put

on. In contrast to this method, the

fleece tape can be put on between

twisting and reeling-up during the

twisting process and therefore does

not require an extra operation. Sample A: CF27.100.10.02.01.D

Product information CF27.D

Page 296

Sample B: experimental production

934 935