Page 949 - ASEAN Chainflex Catalogue 2023

P. 949

Example: ...tested! The igus development of a new twistable, shielded single

®

core cable accounts for this and ensures, due to its special

shield design and structure, that no, or absolutely minimal,

Completely twisted forces act on the shield wire.

As the test clearly shows, massive service life extension can be

observed when compared, for example, to a CF310.250.01.

Test setup:

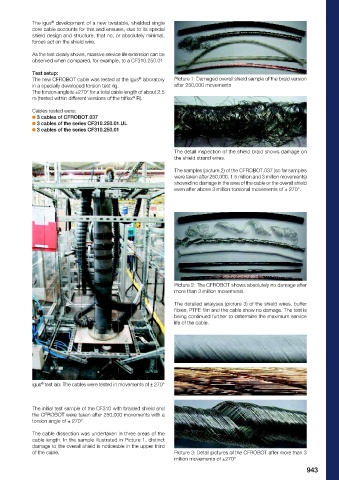

The new CFROBOT cable was tested at the igus laboratory Picture 1: Damaged overall shield sample of the braid version

®

in a specially developed torsion test rig. after 250,000 movements

chainflex cables for e-chain system are designed for Unshielded cables, particularly bundled chainflex types, can The torsion angle is ±270° for a total cable length of about 2.5

®

®

®

application in linear movements and their efficiency has been be successfully used in many twisted applications. m (tested within different versions of the triflex R).

®

proved a million times. In twisting movements with a braided shield, the strand wires

wound in one direction are in tension and the other direction Cables tested were:

But industrial applications and their motion sequences are in compression. This leads quickly to shield breakage. 3 cables of CFROBOT.037

becoming increasingly complex, so that special cables are 3 cables of the series CF310.250.01.UL

needed more and more for torsional movements. The service 3 cables of the series CF310.250.01

life of the different designs are even harder to calculate for

torsion applications, as there are no fixed parameters such

as radii, travels etc. Shielded cables however are particularly The detail inspection of the shield braid shows damage on

vulnerable in torsion applications. Braided shields are generally the shield strand wires.

braided in the opposite directions. Whether a cable survives

the torsional demands is very strongly dependent on the The samples (picture 2) of the CFROBOT.037 (so far samples

application and type of installation.

were taken after 250,000, 1.5 million and 3 million movements)

showed no damage in the area of the cable or the overall shield

even after above 3 million torsional movements of ± 270°.

Picture 2: The CFROBOT shows absolutely no damage after

more than 3 million movements

The detailed analyses (picture 3) of the shield wires, buffer

fibres, PTFE film and the cable show no damage. The test is

being continued further to determine the maximum service

life of the cable.

igus test lab: The cables were tested in movements of ± 270°

®

The initial test sample of the CF310 with braided shield and

the CFROBOT were taken after 250,000 movements with a

torsion angle of ± 270°.

The cable dissection was undertaken in three areas of the

cable length. In the sample illustrated in Picture 1, distinct

At igus , the emphasis is not only on technology but also on Product information CFROBOT damage to the overall shield is noticeable in the upper third

®

aesthetically designed products. The TRC and TRE series of the cable. Picture 3: Detail pictures of the CFROBOT after more than 3

both received the iF-Design-Award. Page 404 million movements of ±270°

942 943