Page 950 - ASEAN Chainflex Catalogue 2023

P. 950

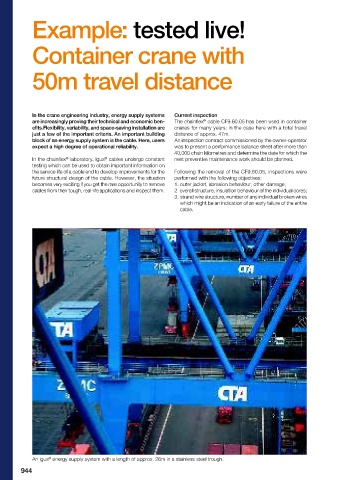

Example: tested live!

Container crane with

50m travel distance

In the crane engineering industry, energy supply systems Current inspection

are increasingly proving their technical and economic ben- The chainflex cable CF9.60.05 has been used in container

®

efits.Flexibility, variability, and space-saving installation are cranes for many years; in the case here with a total travel

just a few of the important criteria. An important building distance of approx. 47m.

block of an energy supply system is the cable. Here, users An inspection contract commissioned by the owner-operator

expect a high degree of operational reliability. was to present a performance balance sheet after more than

40,000 chain kilometres and determine the date for which the

In the chainflex laboratory, igus cables undergo constant next preventive maintenance work should be planned.

®

®

testing which can be used to obtain important information on

the service life of a cable and to develop improvements for the Following the removal of the CF9.60.05, inspections were

future structural design of the cable. However, the situation performed with the following objectives:

becomes very exciting if you get the rare opportunity to remove 1. outer jacket, abrasion behaviour, other damage;

cables from their tough, real-life applications and inspect them. 2. overall structure, insulation behaviour of the individual cores;

3. strand wire structure, number of any individual broken wires

which might be an indication of an early failure of the entire

cable. The energy chain system was filled with many different igus chainflex cables, including the CF9.60.05

®

®

Result regarding 1:

No or only barely measurable traces of abrasion could be

detected on the highly abrasion-resistant TPE outer jacket.

This means that a failure due to abrasion or jacket breakage,

despite the extreme environmental factors (temperature

differences, UV irradiation, etc.), is not expected.

Result regarding 2: An igus energy supply system with a length of approx. 26m

®

The overall structure showed no indications of fatigue and had in a stainless steel trough.

not changed in its pitch length.

Due to the large amount of talc, no abrasion was observed

between the TPE-insulated cores. The high-voltage tests did

not show any age-related changes.

Result regarding 3:

The cable was opened all the way to the copper conductor in

the most stressed section of the radius. Here too, after more

than 40,000 km, the inspection of the individual strand wires

also showed no fatigue breakages which would indicate an

early failure of the cable.

To sum up, it can be said that this cable, which was used in

a real crane application in the trolley of an STS crane, was still The individual elements of the CF9 from the dissected cable.

completely intact even after more than 40,000 km and that

preventive repair work was not required.

A close-up of the completely intact copper conductor. The

Product information CF9 inspection performed over the entire length shows that

Page 114 the conductor is still completely intact and does have any

An igus energy supply system with a length of approx. 26m in a stainless steel trough. individual strand wire breakages.

®

944 945