Page 127 - MiSUMi FA Mechanical Components Economy Series

P. 127

Quality Assurance Economy Series

Linear Guides

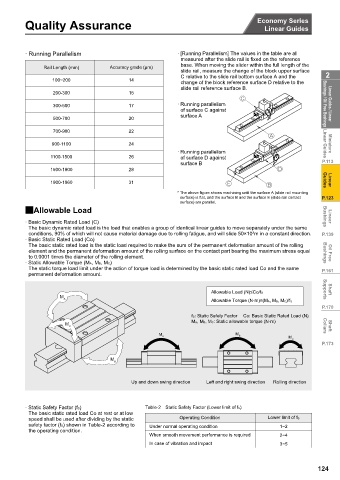

· Running Parallelism · [Running Parallelism] The values in the table are all

measured after the slide rail is fixed on the reference

base. When moving the slider within the full length of the

Rail Length (mm) $FFXUDF\ JUDGH ȝP

slide rail, measure the change of the block upper surface

C relative to the slide rail bottom surface A and the 2

100~200 14

change of the block reference surface D relative to the

slide rail reference surface B.

200-300 15

300-500 17 · Running parallelism Bushings / Oil Free Bushings Linear Guides / Linear

of surface C against

surface A

500-700 20

700-900 22

900-1100 24 Linear Guides Miniature

· Running parallelism

1100-1500 26 of surface D against

surface B P.113

1500-1900 28

1900-1960 31 Guides Linear

* The above figure shows machining until the surface A (slide rail mounting

surface) is flat, and the surface B and the surface E (slide rail contact P.123

surface) are parallel.

2Allowable Load

· Basic Dynamic Rated Load (C) Bushings Linear

The basic dynamic rated load is the load that enables a group of identical linear guides to move separately under the same

conditions, 90% of which will not cause material damage due to rolling fatigue, and will slide 50×10 m in a constant direction. P.139

3

· Basic Static Rated Load (Co)

The basic static rated load is the static load required to make the sum of the permanent deformation amount of the rolling

element and the permanent deformation amount of the rolling surface on the contact part bearing the maximum stress equal Bushings Oil Free

to 0.0001 times the diameter of the rolling element.

· Static Allowable Torque (MA,MB,MC)

The static torque load limit under the action of torque load is determined by the basic static rated load Co and the same P.161

permanent deformation amount.

$OORZDEOH /RDG 1 &R IS Supports Shaft

M

A

$OORZDEOH 7RUTXH 1āP 0A, MB, MC)/fS

P.170

fS: Static Safety Factor Co: Basic Static Rated Load (N)

MA, MB, MC: Static allowable torque (N·m)

M

C Collars Shaft

M B

M A

M C

P.173

M

B

Up and down swing direction Left and right swing direction Rolling direction

· Static Safety Factor (fS) Table-2 Static Safety Factor (Lower limit of fS)

The basic static rated load Co at rest or at low

speed shall be used after dividing by the static Operating Condition Lower limit of fS

safety factor (fS) shown in Table-2 according to Under normal operating condition 1~2

the operating condition.

When smooth movement performance is required 2~4

In case of vibration and impact 3~5

124