Page 131 - MiSUMi FA Mechanical Components Economy Series

P. 131

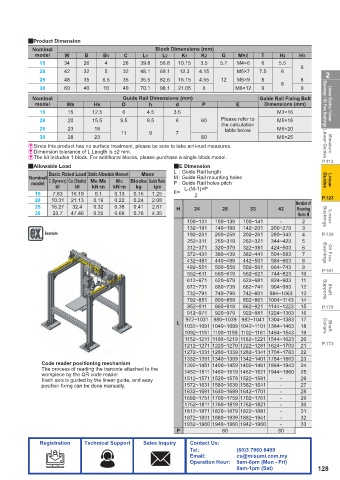

2Product Dimension

Nominal Block Dimensions (mm)

model W B B1 C L1 L2 K1 K2 G M×- T H2 H3

15 34 26 4 26 39.8 56.8 10.15 3.5 5.7 M4×6 6 5.5

6

20 42 32 5 32 48.1 69.1 12.3 4.15 M5×7 7.5 6 2

25 48 35 6.5 35 35.5 82.6 16.15 4.55 12 M6×9 8 8

8

30 60 40 10 40 70.1 98.1 21.05 6 M8×12 9 9

Nominal Guide Rail Dimensions (mm) Guide Rail Fixing Bolt

model WR HR D h d P E Dimensions (mm) Bushings / Oil Free Bushings Linear Guides / Linear

15 15 12.5 6 4.5 3.5 M3×16

20 20 15.5 9.5 8.5 6 60 Please refer to M5×16

the calculation

25 23 18 table below M6×20

11 9 7

30 28 23 80 M6×25

&Since this product has no surface treatment, please be sure to take anti-rust measures. Linear Guides Miniature

&Dimension tolerance of L Length is ±2 mm.

&The kit includes 1 block. For additional blocks, please purchase a single block model.

P.113

2Allowable Load 2E Dimension

Basic Rated Load Static Allowable Moment Mass L : Guide Rail length

Nominal M : Guide Rail mounting holes Guides Linear

model C (Dynamic) Co (Static) MA·MB MC Blocks Guide Rails P : Guide Rail holes pitch

kN kN kN·m kN·m kg kg/m L-(M-1)×P

15 7.83 16.19 0.1 0.13 0.15 1.25 E= 2

20 10.31 21.13 0.16 0.22 0.24 2.08 Number of P.123

25 16.27 32.4 0.32 0.38 0.41 2.67 H 24 28 33 42 Mounting

30 23.7 47.46 0.55 0.68 0.76 4.35 Holes M Bushings Linear

100~131 100~139 100~141 - 2

132~191 140~199 142~201 200~279 3

Example 192~251 200~259 202~261 280~343 4 P.139

252~311 260~319 262~321 344~423 5

312~371 320~379 322~381 424~503 6

372~431 380~439 382~441 504~583 7 Bushings Oil Free

432~491 440~499 442~501 584~663 8

492~551 500~559 502~561 664~743 9

552~611 560~619 562~621 744~823 10 P.161

612~671 620~679 622~681 824~903 11

672~731 680~739 682~741 904~983 12 Supports Shaft

732~791 740~799 742~801 984~1063 13

792~851 800~859 802~861 1064~1143 14

852~911 860~919 862~921 1144~1223 15 P.170

912~971 920~979 922~981 1224~1303 16

972~1031 980~1039 982~1041 1304~1383 17

L

1032~1091 1040~1099 1042~1101 1384~1463 18 Collars Shaft

1092~1151 1100~1159 1102~1161 1464~1543 19

1152~1211 1160~1219 1162~1221 1544~1623 20

1212~1271 1220~1279 1222~1281 1624~1703 21 P.173

1272~1331 1280~1339 1282~1341 1704~1783 22

1332~1391 1340~1399 1342~1401 1784~1863 23

Code reader positioning mechanism 1392~1451 1400~1459 1402~1461 1864~1943 24

The process of reading the barcode attached to the 1452~1511 1460~1519 1462~1521 1944~1960 25

workpiece by the QR code reader.

Each axis is guided by the linear guide, and easy 1512~1571 1520~1579 1522~1581 - 26

position fi xing can be done manually. 1572~1631 1580~1639 1582~1641 - 27

1632~1691 1640~1699 1642~1701 - 28

1692~1751 1700~1759 1702~1761 - 29

1752~1811 1760~1819 1762~1821 - 30

1812~1871 1820~1879 1822~1881 - 31

1872~1931 1880~1939 1882~1941 - 32

1932~1960 1940~1960 1942~1960 - 33

P 60 80

Registration Technical Support Sales Inquiry Contact Us:

Tel: (60)3 7960 8499

Email: cs@misumi.com.my

Operation Hour: 9am-6pm (Mon - Fri)

9am-1pm (Sat) 128