Page 617 - MiSUMi FA Mechanical Components Economy Series

P. 617

13

Economy Series

Quality Assurance Round Posts / Hex Posts

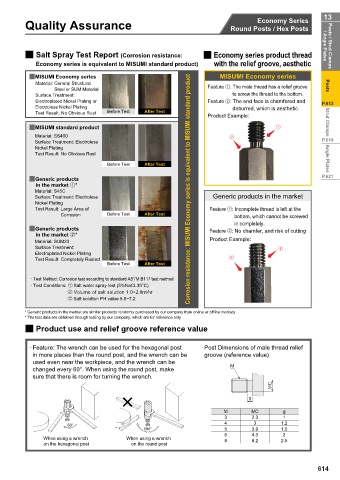

2 Salt Spray Test Report (Corrosion resistance: 2 Economy series product thread / Angle Plates Posts / Strut Clamps

Economy series is equivalent to MISUMI standard product) with the relief groove, aesthetic

2MISUMI Economy series MISUMI Economy series

Material: General Structural Posts

Steel or SUM Material Feature : The male thread has a relief groove

Surface Treatment: to screw the thread to the bottom.

Electroplated Nickel Plating or Feature : The end face is chamfered and P.613

Electroless Nickel Plating deburred, which is aesthetic.

Test Result: No Obvious Rust Before Test After Test

Product Example:

2MISUMI standard product Strut Clamps

Material: SS400

Surface Treatment: Electroless P.619

Nickel Plating

Test Result: No Obvious Rust Angle Plates

Before Test After Test

P.621

2Generic products

in the market *

Material: S45C Corrosion resistance: MISUMI Economy series is equivalent to MISUMI standard product

Surface Treatment: Electroless Generic products in the market

Nickel Plating

Test Result: Large Area of Feature : Incomplete thread is left at the

Corrosion Before Test After Test bottom, which cannot be screwed

in completely.

2Generic products Feature : No chamfer, and risk of cutting

in the market *

Material: SUM23 Product Example:

Surface Treatment:

Electroplated Nickel Plating

Test Result: Completely Rusted

Before Test After Test

· Test Method: Corrosion test according to standard ASTM B117 test method

· Test Conditions: Salt water spray test (5%NaCL35°C)

Volume of salt solution 1.0~2.0ml/hr

Salt solution PH value 6.5~7.2

* Generic products in the market are similar products randomly purchased by our company from online or offline markets

* The test data are obtained through testing by our company, which are for reference only

2 Product use and relief groove reference value

·Feature: The wrench can be used for the hexagonal post ·Post Dimensions of male thread relief

in more places than the round post, and the wrench can be groove (reference value)

used even near the workpiece, and the wrench can be

changed every 60°. When using the round post, make M

sure that there is room for turning the wrench.

MC

g

M MC g

3 2.3 1

60° 4 3 1.2

180° 5 3.9 1.5

6 4.3 2

When using a wrench When using a wrench 8 6.2 2.5

on the hexagonal post on the round post

614