Page 949 - MiSUMi FA Mechanical Components Economy Series

P. 949

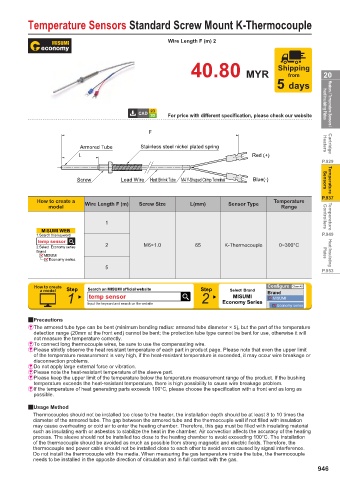

Temperature Sensors Standard Screw Mount K-Thermocouple

Wire Length F (m) 2

Shipping

40.80 MYR from 20

5 days

For price with different specification, please check our website Heat Insulating Plates Heaters / Temperature Sensors /

F

Armored Tube Stainless steel nickel plated spring Heaters Cartridge

L Red (+)

P.929

Screw Lead Wire Heat Shrink Tube M4 Y-Shaped Crimp Terminal Blue(-) Sensors Temperature

P.937

How to create a Temperature

model Wire Length F (m) Screw Size L(mm) Sensor Type Range

1 Controllers Temperature

MISUMI WEB

1.Search this keyword P.949

temp sensor

2.Select Economy series 2 M6×1.0 65 K-Thermocouple 0~300°C

Brand

MISUMI Plates Heat Insulating

Economy series

5

P.953

How to create Search on MISUMI official website Configure Clear All

a model Step Step Select Brand Brand

1 temp sensor 2 MISUMI MISUMI

Economy Series

Input the keyword and search on the website

Economy series

2Precautions

& The armored tube type can be bent (minimum bending radius: armored tube diameter × 5), but the part of the temperature

detection range (20mm at the front end) cannot be bent; the protection tube type cannot be bent for use, otherwise it will

not measure the temperature correctly.

& To connect long thermocouple wires, be sure to use the compensating wire.

& Please strictly observe the heat resistant temperature of each part in product page. Please note that even the upper limit

of the temperature measurement is very high, if the heat-resistant temperature is exceeded, it may occur wire breakage or

disconnection problems.

& Do not apply large external force or vibration.

& Please note the heat-resistant temperature of the sleeve part.

& Please keep the upper limit of the temperature below the temperature measurement range of the product. If the bushing

temperature exceeds the heat-resistant temperature, there is high possibility to cause wire breakage problem.

& If the temperature of heat generating parts exceeds 100°C, please choose the specification with a front end as long as

possible.

2Usage Method

Thermocouples should not be installed too close to the heater, the installation depth should be at least 8 to 10 times the

diameter of the armored tube. The gap between the armored tube and the thermocouple wall if not fi lled with insulation

may cause overheating or cold air to enter the heating chamber. Therefore, this gap must be fi lled with insulating material

such as insulating earth or asbestos to stabilize the heat in the chamber. Air convection aff ects the accuracy of the heating

process. The sleeve should not be installed too close to the heating chamber to avoid exceeding 100°C. The installation

of the thermocouple should be avoided as much as possible from strong magnetic and electric fi elds. Therefore, the

thermocouple and power cable should not be installed close to each other to avoid errors caused by signal interference.

Do not install the thermocouple with the media. When measuring the gas temperature inside the tube, the thermocouple

needs to be installed in the opposite direction of circulation and in full contact with the gas.

946