Page 47 - IGUS Bearing

P. 47

iglidur | High-performance polymers iglidur | Technical data

®

®

Properties and design Load

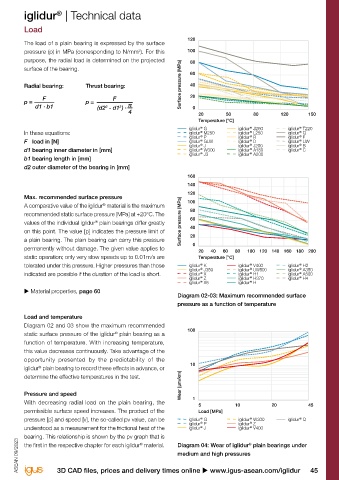

The traditional solution The load of a plain bearing is expressed by the surface 120

®

Hard shells with soft coating. Every lubricated bearing The iglidur solution: pressure (p) in MPa (corresponding to N/mm ). For this 100

2

works according to this principle, and also a number of the self-lubricating effect purpose, the radial load is determined on the projected 80

maintenance-free bearings that are equipped with special surface of the bearing.

sliding layers. However, this soft sliding layer is not strong The high-performance polymers of the iglidur plain 60

®

enough. For high loads, edge pressure or oscillations, it is bearings consist of: Radial bearing: Thrust bearing: Surface pressure [MPa] 40

easily removed. F F 20

● Base polymer p = d1 · b1 p = 2 2 π

Base polymers and technical fibres ● Fibres and filling material (d2 - d1 ) · 4 0 20 50 80 120 150

The radial pressure with which the bearings are loaded ● Solid lubricants Temperature [°C]

is received by the polymer material. In the contact area, iglidur G iglidur J260 iglidur T220

®

®

®

®

®

®

this material provides a support to the shaft. The polymer These components are not applied in layers, In these equations: iglidur M250 iglidur L250 iglidur Q

iglidur R

iglidur F

iglidur P

®

®

®

®

®

®

base material ensures that the lubricants do not receive but instead are mixed together homogeneously. F load in [N] iglidur GLW iglidur D iglidur UW

iglidur J200

iglidur B

iglidur J

®

®

®

®

®

®

a surface pressure that is too high. The base material is The advantage of this design is clear when the d1 bearing inner diameter in [mm] iglidur W300 iglidur A180 iglidur C

iglidur J3

iglidur A200

®

®

also reinforced by technical fibres or filling materials. These requirements on the bearings surface are studied: b1 bearing length in [mm]

additional materials stabilise the bearing especially in cases d2 outer diameter of the bearing in [mm]

of continuous load. 1. The coefficient of friction, which is determined 160

especially by the surface of the bearing, should 140

Incorporated self-lubrication be as low as possible. Max. recommended surface pressure 120

The solid lubricants are, as microscopic particles, embedded A comparative value of the iglidur material is the maximum 100

®

in millions of tiny chambers of the material. From these 2. The surface cannot be removed by forces that recommended static surface pressure [MPa] at +20°C. The 80

chambers, the plain bearings release tiny amounts of solid act on the bearing. values of the individual iglidur plain bearings differ greatly Surface pressure [MPa] 60

®

lubricants during movement. This is adequate to sufficiently on this point. The value [p] indicates the pressure limit of 40

lubricate the immediate surrounding area. The lubricants 3. The wearing force acts especially on the surface a plain bearing. The plain bearing can carry this pressure 20

help to reduce the iglidur bearing's coefficient of friction. of the bearing, for this the bearing must be permanently without damage. The given value applies to 0 20 40 60 80 100 120 140 160 180 200

®

They are not indispensable for the bearing's function, but capable of high resistance. static operation; only very slow speeds up to 0.01m/s are Temperature [°C]

have a supporting effect. Since they are embedded in the tolerated under this pressure. Higher pressures than those iglidur K iglidur V400 iglidur H2

®

®

®

®

®

®

tiny chambers, they cannot be forced out. They are always indicated are possible if the duration of the load is short. iglidur J350 iglidur UW500 iglidur A350

iglidur A500

iglidur X

iglidur H1

®

®

®

®

®

®

there as soon as the bearing or the shaft is set in motion. One universal material, which can fulfil all these tasks iglidur Z iglidur H370 iglidur H4

iglidur H

iglidur X6

®

®

equally well, unfortunately does not exist yet. That is u Material properties, page 60

why iglidur plain bearings work differently. Different Diagram 02-03: Maximum recommended surface

®

components of the iglidur materials give the bearings pressure as a function of temperature

®

their properties: Load and temperature

Diagram 02 and 03 show the maximum recommended

®

● The base polymers are responsible for the static surface pressure of the iglidur plain bearing as a 100

resistance to wear. function of temperature. With increasing temperature,

● Fibres and filling materials reinforce the bearing this value decreases continuously. Take advantage of the

so that high forces or edge loads are possible. opportunity presented by the predictability of the

®

● Solid lubricants lubricate the bearing iglidur plain bearing to record these effects in advance, or 10

Wear [µm/km]

independently and prevent friction of the system. determine the effective temperatures in the test.

Pressure and speed

With decreasing radial load on the plain bearing, the 1 5 10 20 45

permissible surface speed increases. The product of the Load [MPa]

pressure [p] and speed [v], the so-called pv value, can be iglidur G iglidur W300 iglidur Q

®

®

®

Picture 04: Polymer granulate; basis compound of the understood as a measurement for the frictional heat of the iglidur P iglidur Z

®

®

iglidur J

iglidur V400

®

®

lubrication-free and predictable iglidur plain bearings bearing. This relationship is shown by the pv graph that is

®

ASEAN 09/2023 ASEAN 09/2023 the first in the respective chapter for each iglidur material. Diagram 04: Wear of iglidur plain bearings under

®

®

medium and high pressures

44 Online tools and more information u www.igus-asean.com/iglidur 3D CAD files, prices and delivery times online u www.igus-asean.com/iglidur 45