Page 55 - IGUS Bearing

P. 55

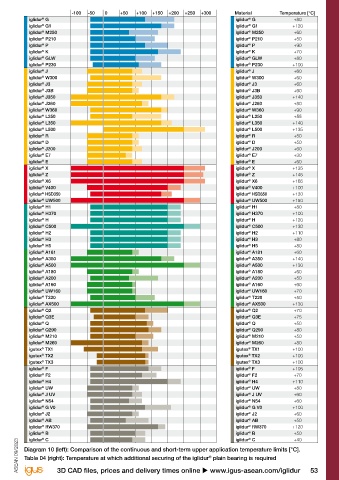

iglidur | Technical data iglidur G -100 -50 0 +50 +100 +150 +200 +250 +300 Material Temperature [°C]

®

+80

iglidur G

®

®

®

®

Temperatures iglidur G1 iglidur G1 +120

iglidur M250

®

iglidur M250

+60

®

iglidur P210 iglidur P210 +50

®

®

The temperature resistance of high-performance polymer addition to the press-fit. The table 04 shows the temperature iglidur P iglidur P +90

®

®

plain bearings is usually underestimated. Data is often at which additional securing of the iglidur plain bearing is iglidur K iglidur K +70

®

®

®

®

®

found in the literature about the continuous operating required, even under low axial loads. The greater the forces, iglidur GLW iglidur GLW +80

iglidur P230 iglidur P230 +100

®

®

temperature. The continuous operating temperature is the more reasons to engage such a fastening. iglidur J iglidur J +60

®

®

the highest temperature, which the plastic can withstand iglidur W300 iglidur W300 +60

®

®

®

®

for a period of time without a reduction in the tensile Temperature and load iglidur J3 iglidur J3 +60

+60

®

®

strength of the material above or below a prespecified The diagrams 02 and 03 (u Page 45) show the maximum iglidur J3B iglidur J3B +140

iglidur J350

iglidur J350

®

®

value. This standardised test however yields only a less recommended surface pressure [p] of the iglidur plain iglidur J260 iglidur J260 +80

®

®

®

®

®

relevant characteristic value, as bearings are almost always bearings as a function of temperature. With increasing iglidur W360 iglidur W360 +90

®

®

subjected to a load. The application temperatures of the temperature, this value decreases continuously. With plain iglidur L250 iglidur L250 +55

®

iglidur L350 iglidur L350 +140

®

materials are more revealing. bearings it is important to note that, due to the friction, iglidur L500 iglidur L500 +135

®

®

®

the bearing temperature may be higher than the ambient iglidur R iglidur R +50

®

®

iglidur D iglidur D +50

®

Application temperatures temperature. iglidur J200 iglidur J200 +60

®

®

The minimum application temperature is the temperature iglidur E7 iglidur E7 +30

®

®

below which the material is so rigid and hard that it Coefficient of thermal expansion iglidur E iglidur E +60

®

®

®

®

becomes too brittle for standard applications. The maximum The thermal expansion of polymers is approximately iglidur X iglidur X +135

+145

iglidur Z

iglidur Z

®

®

continuous application temperature is the temperature the 10 to 20 times higher than metals. In contrast to metal, iglidur X6 iglidur X6 +165

®

®

material can endure for a longer period of time without the this expansion is non-linear in plastics. The coefficient iglidur V400 iglidur V400 +100

®

®

®

®

properties changing considerably. of thermal expansion of the iglidur plain bearing is a iglidur HSD350 iglidur HSD350 +130

®

iglidur UW500 iglidur UW500 +150

®

®

The maximum, short-term application temperature is the significant reason for the bearing clearance. At the given iglidur H1 iglidur H1 +80

®

®

temperature above which the material becomes so soft, application clearance, seizing of the bearing to the shaft iglidur H370 iglidur H370 +100

®

®

®

®

that it can only withstand small external loads. "Short term" does not occur at high temperatures. The coefficient of iglidur H iglidur H +120

iglidur C500

iglidur C500

+130

®

®

is defined as a period of a few minutes. thermal expansion of iglidur plain bearings was examined iglidur H2 iglidur H2 +110

®

®

®

If the plain bearings are moved axially or axial forces occur, for significant temperature ranges and the results are given iglidur H3 iglidur H3 +80

®

®

®

®

there is more opportunity for the bearing to lose press-fit. in the individual materials tables, at the start of each chapter. iglidur H5 iglidur H5 +80

iglidur A181

+60

iglidur A181

®

®

In these cases, axial securing of the bearing is necessary in iglidur A350 iglidur A350 +140

®

®

iglidur A500 iglidur A500 +130

®

®

iglidur A180 iglidur A180 +60

®

®

iglidur A200 iglidur A200 +50

®

®

iglidur A160 iglidur A160 +60

®

®

iglidur UW160 iglidur UW160 +70

®

®

iglidur T220 iglidur T220 +50

®

®

iglidur AX500 iglidur AX500 +130

®

®

®

iglidur Q2 iglidur Q2 +70

®

®

®

iglidur Q3E iglidur Q3E +75

iglidur Q iglidur Q +50

®

®

iglidur Q290 iglidur Q290 +80

®

®

®

iglidur M210 iglidur M210 +50

®

iglidur M260 iglidur M260 +80

®

®

igutex TX1 igutex TX1 +100

®

®

®

®

igutex TX2 igutex TX2 +100

igutex TX3 igutex TX3 +100

®

®

®

®

iglidur F iglidur F +105

iglidur F2 iglidur F2 +70

®

®

iglidur H4 iglidur H4 +110

®

®

®

®

iglidur UW iglidur UW +80

®

®

iglidur J UV iglidur J UV +60

iglidur N54 iglidur N54 +60

®

®

®

iglidur G V0 iglidur G V0 +100

®

iglidur J2 iglidur J2 +60

®

®

iglidur AB iglidur AB +50

®

®

®

iglidur RW370 iglidur RW370 +120

®

iglidur B iglidur B +50

®

®

iglidur C

+40

iglidur C

®

®

ASEAN 09/2023 ASEAN 09/2023 Table 04 (right): Temperature at which additional securing of the iglidur plain bearing is required

Picture 06: Material tests are possible up to +250°C Diagram 10 (left): Comparison of the continuous and short-term upper application temperature limits [°C].

®

52 Online tools and more information u www.igus-asean.com/iglidur 3D CAD files, prices and delivery times online u www.igus-asean.com/iglidur 53