Page 710 - IGUS Bearing

P. 710

iglidur PRT | Technical data iglidur PRT | Technical data

®

®

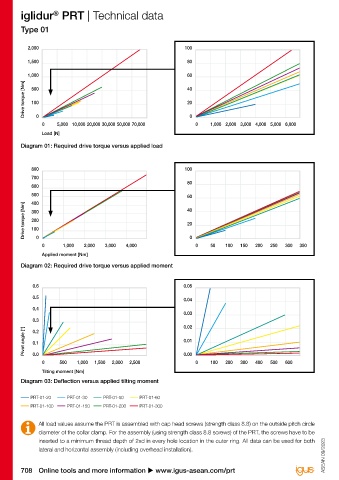

Type 01 Type 04

2,000 100 500 100

1,500 80 400 80

1,000 60 300 60

Drive torque [Nm] 500 40 Drive torque [Nm] 200 40

20

100

20

100

0

0 5,000 10,000 20,000 30,000 50,000 70,000 0 0 1,000 2,000 3,000 4,000 5,000 6,000 0 0 2,000 4,000 6,000 8,000 10,000 12,000 0 0 1,000 2,000 3,000 4,000 5,000 6,000

Load [N] Load [N]

Diagram 01: Required drive torque versus applied load Diagram 01: Required drive torque versus applied load

800 100 200 100

700

80 160 80

600

500 60 120 60

400

Drive torque [Nm] 300 40 Drive torque [Nm] 80 40

200

40

20

20

100

0

0 1,000 2,000 3,000 4,000 0 0 50 100 150 200 250 300 350 0 0 200 400 600 800 1,000 1,200 0 0 50 100 150 200 250 300 350

Applied moment [Nm] Applied moment [Nm]

Diagram 02: Required drive torque versus applied moment Diagram 02: Required drive torque versus applied moment

0.6 0.05 0.5 0.10

0.5 0.04 0.4 0.08

0.4

0.03 0.3 0.06

0.3

0.02 0.2 0.04

Pivot angle [°] 0.1 0.01 Pivot angle [°] 0.1 0.02

0.2

0.0

0 500 1,000 1,500 2,000 2,500 0.00 0 100 200 300 400 500 600 0 0 200 400 600 800 1000 1200 0.00 0 100 200 300 400 500 600

Tilting moment [Nm] Tilting moment [Nm]

Diagram 03: Deflection versus applied tilting moment Diagram 03: Deflection versus applied tilting moment

PRT-01-20 PRT-01-30 PRT-01-50 PRT-01-60 PRT-04-50 PRT-04-60 PRT-04-100

PRT-01-100 PRT-01-150 PRT-01-200 PRT-01-300 PRT-04-150 PRT-04-200 PRT-04-300

All load values assume the PRT is assembled with cap head screws (strength class 8.8) on the outside pitch circle

diameter of the collar clamp. For the assembly (using strength class 8.8 screws) of the PRT, the screws have to be

inserted to a minimum thread depth of 2xd in every hole location in the outer ring. All data can be used for both

lateral and horizontal assembly (including overhead installation). ASEAN 09/2023 ASEAN 09/2023

708 Online tools and more information u www.igus-asean.com/prt 3D CAD files, prices and delivery time online u www.igus-asean.com/prt 709