Page 51 - IGUS Linear

P. 51

drylin linear technology | Curved rails and profiles drylin linear technology | Design rules

®

®

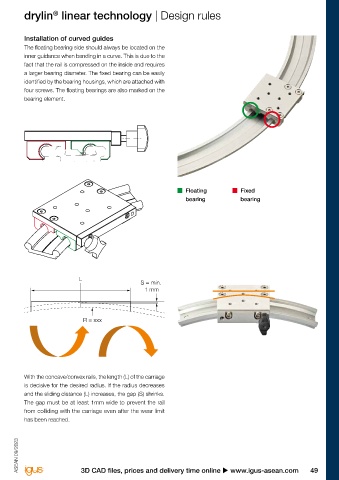

drylin curved linear guide profiles Installation of curved guides

®

igus provides customised curved rails for the drylin W The floating bearing side should always be located on the

®

®

product range. This is especially for the requirements in inner guidance when bending in a curve. This is due to the

operating ergonomics, e.g. guiding monitors and control fact that the rail is compressed on the inside and requires

systems in a radius to ensure safe and easy accessibility. a larger bearing diameter. The fixed bearing can be easily

New standards can be set in design and construction with identified by the bearing housings, which are attached with

a drylin curved guide. four screws. The floating bearings are also marked on the

®

®

● Lubrication-free drylin W carriages for curved rails bearing element.

u Page 103

● Variable profile directions

● Torque-resistant alternative to curved tube profiles

● Bending option depending on the radius, rail length,

bearing/carriage and mounting

● Customised project service

Bending options Floating Fixed

bearing bearing

Bending direction 1 = convex

Curved drylin linear technology - for ergonomic L S = min.

®

operation and optimal field of view 1 mm

Bending direction 2 = concave

Bending can give rise to surface changes (anodising,

torsion) as a result of the deformation. Rail profiles with clear

anodised (CA) surfaces that are undersized by up to 0.15 R = xxx

below nominal diameters are used to improve the surface

finish of the curved rails. We recommend a bend radius of

no less than 300mm and would like to point out that the Bending direction 3 = curved bending

surface finish quality after the bending process depends

on the material quality. It may vary from batch to batch.

With the concave/convex rails, the length (L) of the carriage

is decisive for the desired radius. If the radius decreases

and the sliding distance (L) increases, the gap (S) shrinks.

Bending direction 4 = curved bending

The gap must be at least 1mm wide to prevent the rail

Different radii and bending directions available upon from colliding with the carriage even after the wear limit

Curved rail profiles request has been reached.

u Page 98

More Information and checklist online

u www.igus-asean.com/curved ASEAN 09/2023 ASEAN 09/2023

48 Online tools and more information u www.igus-asean.com 3D CAD files, prices and delivery time online u www.igus-asean.com 49