Page 427 - ASEAN Chainflex Catalogue 2023

P. 427

CFTHERMO PVC iguPUR PUR TPE Basic requirements low 1 2 3 4 5 6 7 highest CFTHERMO

PUR Travel distance unsupported 1 2 3 4 5 6 ≥ 400m PUR

12.5 x d ® Oil resistance none 1 2 3 4 highest 12.5 x d

Thermocouple cable | PUR | chainflex CFTHERMO Class 5.4.3.1 Torsion none 1 2 3 4 ±360°

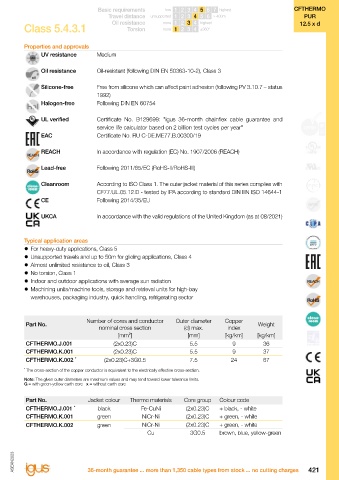

Properties and approvals

z For heavy duty applications UV resistance Medium

z PUR outer jacket

z Oil-resistant and coolant-resistant Oil resistance Oil-resistant (following DIN EN 50363-10-2), Class 3

z PVC and halogen-free

z Notch-resistant Silicone-free Free from silicone which can affect paint adhesion (following PV 3.10.7 – status

z Hydrolysis and microbe-resistant 1992)

Halogen-free Following DIN EN 60754

UL verified Certificate No. B129699: "igus 36-month chainflex cable guarantee and

Dynamic information service life calculator based on 2 billion test cycles per year"

®

Bend radius e-chain linear minimum 12.5 x d EAC Certificate No. RU C-DE.ME77.B.00300/19

flexible minimum 10 x d

fixed minimum 5 x d REACH In accordance with regulation (EC) No. 1907/2006 (REACH)

®

Temperature e-chain linear -25°C up to +80°C

flexible -40°C up to +80°C (following DIN EN 60811-504) Lead-free Following 2011/65/EC (RoHS-II/RoHS-III)

fixed -50°C up to +80°C (following DIN EN 50305)

v max. unsupported 2m/s Cleanroom According to ISO Class 1. The outer jacket material of this series complies with

gliding 1m/s CF77.UL.05.12.D - tested by IPA according to standard DIN EN ISO 14644-1

a max. 20m/s² CE Following 2014/35/EU

Travel distance Unsupported travels and up to 50m for gliding applications, Class 4 UKCA In accordance with the valid regulations of the United Kingdom (as at 08/2021)

Cable structure

Conductor Conductor consisting of a flexible special alloy. Typical application areas

u Product range table z For heavy-duty applications, Class 5

Core insulation Mechanically high-quality TPE mixture. z Unsupported travels and up to 50m for gliding applications, Class 4

z Almost unlimited resistance to oil, Class 3

Core structure The individual cores are wound in layers with a short pitch length. z No torsion, Class 1

z Indoor and outdoor applications with average sun radiation

Core identification According to thermo specification. z Machining units/machine tools, storage and retrieval units for high-bay

u Product range table warehouses, packaging industry, quick handling, refrigerating sector

Intermediate layer Fleece taping over the external layer.

Overall shield Extremely bending-resistant braiding made of tinned copper wires. Part No. Number of cores and conductor Outer diameter Copper Weight

Coverage linear approx. 70%, optical approx. 90% nominal cross section (d) max. index

Outer jacket Low-adhesion, halogen-free, highly abrasion resistant PUR mixture, adapted [mm²] [mm] [kg/km] [kg/km]

®

to suit the requirements in e-chains (following DIN EN 50363-10-2) CFTHERMO.J.001 (2x0.23)C 5.5 9 36

Colour: According to thermo specification u Product range table CFTHERMO.K.001 (2x0.23)C 5.5 9 37

Electrical information CFTHERMO.K.002 * (2x0.23)C+3G0.5 7.5 24 67

Nominal voltage 300/300V (following DIN VDE 0298-3) * The cross-section of the copper conductor is equivalent to the electrically effective cross-section.

Note: The given outer diameters are maximum values and may tend toward lower tolerance limits.

Testing voltage 1,500V G = with green-yellow earth core x = without earth core

Part No. Jacket colour Thermo materials Core group Colour code

CFTHERMO.J.001 * black Fe-CuNi (2x0.23)C + black, - white

CFTHERMO.K.001 green NiCr-Ni (2x0.23)C + green, - white

NiCr-Ni

(2x0.23)C

+ green, - white

green

CFTHERMO.K.002

Example image Cu 3G0.5 brown, blue, yellow-green

ASEAN2023 ASEAN2023

420 EPLAN download, configurators u www.igus-asean.com/CFTHERMO 36-month guarantee ... more than 1,350 cable types from stock ... no cutting charges 421