Page 1006 - MiSUMi FA Mechanical Components Economy Series

P. 1006

[Technical Data]

Designing of Chain Drive Mechanism 4

Installation Way Horizontal Arrangement Lubrication

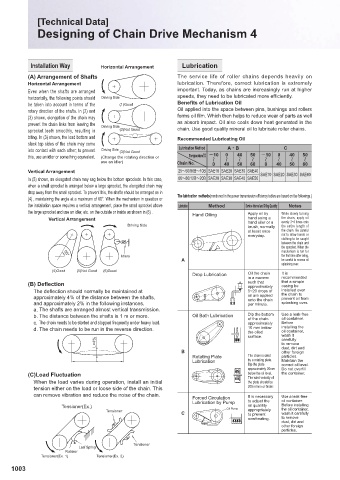

(A) Arrangement of Shafts The service life of roller chains depends heavily on

Horizontal Arrangement lubrication. Therefore, correct lubrication is extremely

Even when the shafts are arranged important. Today, as chains are increasingly run at higher

horizontally, the following points should Driving Side speeds, they need to be lubricated more effi ciently.

be taken into account in terms of the (1)Good Benefi ts of Lubrication Oil

rotary direction of the shafts. In (2) and Oil applied into the space between pins, bushings and rollers

(3) shown, elongation of the chain may forms oil fi lm. Which then helps to reduce wear of parts as well

prevent the chain links from leaving the Driving Side as absorb impact. Oil also cools down heat generated in the

sprocket teeth smoothly, resulting in (2)Not Good chain. Use good quality mineral oil to lubricate roller chains.

biting. In (3) shown, the load bottom and Recommended Lubricating Oil

slack top sides of the chain may come

into contact with each other; to prevent Driving Side (3)Not Good Lubrication Method ACB C

this, use an idler or something equivalent. (Change the rotating direction or Temperature (A) 10 0 40 50 10 0 40 50

use an idler) Chain No. 0 ։ 40 ։ 50 ։ 60 ։ 0 ։ 40 ։ 50 ։ 60 ։

Vertical Arrangement 25։50/06B։10B SAE10 SAE20 SAE30 SAE40 SAE10 SAE20 SAE30 SAE40

In (5) shown, an elongated chain may sag below the bottom sprockets. In this case, 60։80/12B։20B SAE20 SAE30 SAE40 SAE50

when a small sprocket is arranged below a large sprocket, the elongated chain may

drop away from the small sprocket. To prevent this, the shafts should be arranged as in The lubrication methods(mentioned in the power transmission effi ciency tables are based on the followings.)

(4) , maintaining the angle at a maximum of 60°. When the mechanism in question or

the installation space requires a vertical arrangement, place the small sprocket above Lubrication Method Service Interval and Oiling Quantity Notes

the large sprocket and use an idler, etc. on the outside or inside as shown in (6) . Hand Oiling Apply oil by While slowly turning

Vertical Arrangement hand using a the chain, apply oil

evenly 3~4 times onto

Driving Side hand oiler or a the entire length of

brush, normally

at least once the chain. Be careful

everyday. not to allow hands or

clothing to be caught

between the chain and

the sprocket. When the

mechanism is run for

Idlers the fi rst time after oiling,

60°

A be careful to excess oil

splashing over.

(4)Good (5)Not Good (6)Good

Drop Lubrication Oil the chain It is

in a manner recommended

(B) Defl ection such that that a simple

approximately casing be

The defl ection should normally be maintained at 5~20 drops of installed over

the chain to

approximately 4% of the distance between the shafts, oil are applied prevent oil from

onto the chain

and approximately 2% in the following instances. per minute. splashing over.

a. The shafts are arranged almost vertical transmission.

b. The distance between the shafts is 1 m or more. Oil Bath Lubrication Dip the bottom Use a leak-free

oil container.

of the chain

c. The chain needs to be started and stopped frequently under heavy load. approximately Before

d. The chain needs to be run in the reverse direction. 10 mm below installing the

the oiled oil container,

surface. wash it

L×4% carefully

to remove

B dust, dirt and

other foreign

Rotating Plate The chain is oiled particles.

L Lubrication by a rotating plate. Maintain the

Dip the plate correct oil level.

approximately 20mm Do not overfi ll

(C)Load Fluctuation below the oil level. the container.

The wind velocity of

When the load varies during operation, install an initial the plate should be

tension either on the load or loose side of the chain. This 200 m/min or faster.

can remove vibration and reduce the noise of the chain. It is necessary Use a leak-free

Forced Circulation

Lubrication by Pump to adjust the oil container.

Tensioner(Ex.) Oil Pump oil quantity Before installing

the oil container,

Tensioner appropriately

C to prevent wash it carefully

overheating. to remove

dust, dirt and

other foreign

particles.

Tensioner

Leaf Spring

Rubber

Tensioner(Ex. 1) Tensioner(Ex. 2)

1003