Page 1002 - MiSUMi FA Mechanical Components Economy Series

P. 1002

[Technical Data]

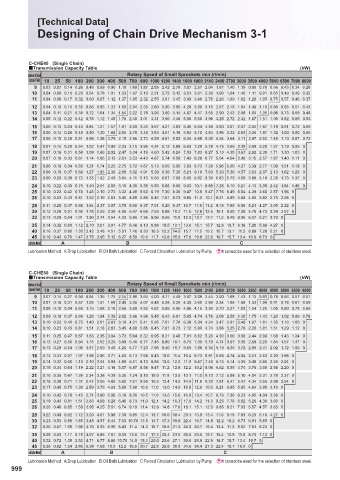

Designing of Chain Drive Mechanism 3-1

C-CHE40 (Single Chain)

ӍTransmission Capacity Table (kW)

Number of Small Rotary Speed of Small Sprockets min (r/min)

Sprocket Teeth 10 25 50 100 200 300 400 500 700 900 1000 1200 1400 1600 1800 2100 2400 2700 3000 3500 4000 5000 6500 7000 8000

9 0.03 0.07 0.14 0.26 0.48 0.69 0.90 1.10 1.49 1.87 2.05 2.42 2.78 3.07 2.57 2.04 1.67 1.40 1.19 0.95 0.78 0.56 0.43 0.34 0.28

10 0.04 0.08 0.16 0.29 0.54 0.78 1.01 1.23 1.67 2.10 2.31 2.72 3.12 3.51 3.01 2.39 1.96 1.64 1.40 1.11 0.91 0.65 0.49 0.40 0.32

11 0.04 0.09 0.17 0.32 0.60 0.87 1.12 1.37 1.85 2.32 2.55 3.01 3.45 3.89 3.48 2.76 2.26 1.89 1.62 1.28 1.05 0.75 0.57 0.46 0.37

12 0.04 0.10 0.19 0.35 0.66 0.95 1.23 1.50 2.04 2.55 2.80 3.30 3.80 4.28 3.96 3.15 2.57 2.16 1.84 1.46 1.19 0.86 0.65 0.51 0.43

13 0.04 0.11 0.21 0.39 0.72 1.04 1.34 1.64 2.22 2.78 3.06 3.60 4.14 4.67 4.47 3.55 2.90 2.43 2.08 1.65 1.35 0.96 0.73 0.58 0.48

14 0.05 0.12 0.22 0.42 0.78 1.12 1.45 1.78 2.40 3.01 3.31 3.90 4.48 5.06 5.00 3.96 3.25 2.72 2.32 1.87 1.51 1.09 0.82 0.65 0.53

15 0.05 0.13 0.24 0.45 0.84 1.21 1.57 1.91 2.59 3.25 3.57 4.21 4.83 5.45 5.54 4.39 3.60 3.01 2.57 2.04 1.67 1.19 0.91 0.72 0.59

16 0.06 0.14 0.26 0.48 0.90 1.30 1.68 2.05 2.78 3.48 3.83 4.51 5.18 5.84 6.10 4.84 3.96 3.32 2.83 2.25 1.87 1.32 1.00 0.80 0.65

17 0.06 0.15 0.28 0.51 0.96 1.38 1.79 2.19 2.96 3.72 4.09 4.81 5.53 6.24 6.68 5.30 4.34 3.64 3.11 2.47 2.02 1.45 1.10 0.87 0.72

18 0.07 0.16 0.29 0.54 1.02 1.47 1.90 2.33 3.15 3.95 4.34 5.12 5.88 6.63 7.28 5.78 4.73 3.96 3.39 2.69 2.20 1.57 1.19 0.95 0

19 0.07 0.16 0.31 0.58 1.09 1.66 2.02 2.47 3.34 4.19 4.60 5.42 6.24 7.03 7.83 6.27 5.13 4.30 3.67 2.92 2.39 1.71 1.30 1.03 0

20 0.07 0.18 0.33 0.61 1.14 1.65 2.13 2.61 3.53 4.43 4.87 5.74 6.59 7.43 8.28 6.77 5.54 4.64 3.96 3.15 2.57 1.87 1.40 1.11 0

21 0.08 0.19 0.34 0.65 1.21 1.74 2.25 2.75 3.72 4.67 5.13 6.05 6.95 7.83 8.73 7.28 5.96 5.00 4.27 3.39 2.77 1.98 1.51 1.19 0

22 0.08 0.19 0.37 0.68 1.27 1.83 2.36 2.89 3.92 4.91 5.39 6.36 7.30 8.21 9.18 7.83 5.39 5.36 4.57 3.63 2.97 2.13 1.62 1.28 0

23 0.09 0.20 0.38 0.72 1.33 1.92 2.48 3.04 4.11 5.15 5.66 6.67 7.68 8.65 9.62 8.36 6.83 5.73 4.89 3.88 3.18 2.28 1.73 1.37 0

24 0.10 0.22 0.40 0.75 1.40 2.01 2.60 3.18 4.30 5.39 5.93 6.98 8.06 9.03 10.1 8.88 7.28 6.10 5.21 4.13 3.39 2.42 1.84 1.46 0

25 0.10 0.22 0.42 0.78 1.45 2.10 2.72 3.32 4.49 5.63 6.19 7.30 8.36 9.47 10.5 9.47 7.76 6.49 5.54 4.39 3.60 2.57 1.96 0

26 0.10 0.23 0.43 0.81 1.52 2.19 2.83 3.46 4.68 5.88 6.46 7.61 8.73 9.85 11.0 10.1 8.21 6.89 5.88 4.66 3.82 2.73 2.08 0

28 0.11 0.25 0.47 0.88 1.64 2.37 3.07 3.75 5.08 6.37 7.01 8.28 9.47 10.7 11.9 11.2 9.18 7.68 6.56 5.21 4.27 3.05 2.32 0

30 0.12 0.28 0.51 0.95 1.78 2.55 3.30 4.04 5.47 6.66 7.53 8.88 10.2 11.5 12.8 12.5 10.1 8.50 7.28 5.78 4.73 3.39 2.57 0

32 0.13 0.29 0.54 1.01 1.90 2.74 3.54 4.33 5.86 7.36 8.06 9.55 11.0 12.3 13.7 13.7 11.2 9.40 8.06 6.37 5.21 3.73 0

35 0.14 0.32 0.60 1.12 2.10 3.01 3.91 4.77 6.46 8.13 8.88 10.5 12.1 13.6 15.1 15.7 12.8 10.7 9.18 7.28 5.96 4.27 0

40 0.16 0.37 0.69 1.30 2.42 3.48 4.51 5.51 7.46 9.33 10.3 12.2 14.0 15.7 17.5 19.2 15.7 13.1 11.2 8.88 7.28 5.21 0

45 0.19 0.43 0.79 1.47 2.75 3.95 5.13 6.27 8.50 10.6 11.7 13.8 15.8 17.8 19.8 22.8 18.7 15.7 13.4 10.6 8.73 0

Lubrication Method A B C

Lubrication Method A:Drop Lubrication B:Oil Bath Lubrication C:Forced Circulation Lubrication by Pump & It cannot be used for the selection of stainless steel.

C-CHE50 (Single Chain)

ӍTransmission Capacity Table (kW)

Number of Small Rotary Speed of Small Sprockets min (r/min)

Sprocket Teeth 10 25 50 100 200 300 400 500 700 900 1000 1200 1400 1600 1800 2100 2400 2700 3000 3500 4000 4500 5000 5500 6000

9 0.07 0.14 0.27 0.50 0.94 1.35 1.75 2.14 2.90 3.64 4.00 4.71 4.49 3.67 3.08 2.44 2.00 1.68 1.43 1.13 0.93 0.78 0.66 0.57 0.51

10 0.07 0.16 0.31 0.57 1.05 1.51 1.69 2.40 3.25 4.07 4.48 5.28 5.26 4.30 3.60 2.86 2.34 1.96 1.68 1.33 1.09 0.91 0.78 0.67 0.59

11 0.08 0.18 0.34 0.63 1.16 1.68 2.18 2.66 3.60 4.52 4.97 5.86 6.06 4.96 4.16 3.30 2.70 2.27 1.93 1.54 1.25 1.05 0.90 0.78 0.69

12 0.09 0.19 0.37 0.69 1.28 1.84 2.39 2.92 3.96 4.96 5.45 6.43 6.91 5.65 4.74 3.76 3.08 2.58 2.20 1.75 1.43 1.20 1.02 0.89 0.78

13 0.10 0.22 0.40 0.75 1.40 2.01 2.61 3.19 4.31 5.41 5.95 7.01 7.76 6.38 5.34 4.24 3.47 2.91 2.48 1.97 1.61 1.35 1.16 1.00 0

14 0.10 0.23 0.43 0.81 1.51 2.18 2.83 3.45 4.68 5.86 6.45 7.61 8.73 7.12 5.98 4.74 3.88 3.25 2.76 2.20 1.81 1.51 1.29 1.12 0

15 0.11 0.25 0.47 0.87 1.63 2.35 3.04 3.72 5.04 6.32 6.95 8.21 9.40 7.91 6.62 5.26 4.30 3.60 3.08 2.44 2.00 1.68 1.43 1.24 0

16 0.12 0.27 0.50 0.94 1.75 2.52 3.26 3.99 5.40 6.77 7.45 8.80 10.1 8.73 7.30 5.79 4.74 3.97 3.39 2.69 2.20 1.84 1.57 1.37 0

17 0.13 0.29 0.54 1.00 1.87 2.69 3.48 4.26 5.77 7.23 7.98 9.40 10.7 9.55 7.98 6.34 5.19 4.35 3.72 2.95 2.41 2.02 1.72 1.50 0

18 0.13 0.31 0.57 1.07 1.98 2.86 3.71 4.53 6.13 7.68 8.43 10.0 11.4 10.4 8.73 6.91 5.65 4.74 4.04 3.21 2.63 2.20 1.88 0

19 0.14 0.32 0.60 1.13 2.10 3.04 3.93 4.80 6.51 8.13 8.95 10.6 12.2 11.3 9.47 7.46 6.13 5.14 4.39 3.48 2.85 2.39 2.04 0

20 0.15 0.34 0.64 1.19 2.22 3.21 4.16 5.07 6.87 8.58 9.47 11.2 12.8 12.2 10.2 8.06 6.62 5.55 4.74 3.76 3.08 2.58 2.20 0

21 0.16 0.36 0.67 1.26 2.34 3.38 4.38 5.35 7.24 9.10 10.0 11.8 13.5 13.1 11.0 8.73 7.12 5.98 5.10 4.04 3.31 2.78 2.37 0

22 0.16 0.38 0.71 1.37 2.47 3.55 4.60 5.62 7.61 9.55 10.5 12.4 14.2 14.0 11.8 9.33 7.61 6.41 5.47 4.34 3.55 2.98 2.54 0

23 0.17 0.40 0.75 1.39 2.59 3.73 4.83 5.90 7.98 10.0 11.0 13.0 14.9 15.0 12.6 10.0 8.21 6.85 5.85 4.64 3.80 3.19 0

24 0.19 0.42 0.78 1.45 2.71 3.90 5.06 6.18 8.36 10.5 11.6 13.6 15.6 16.0 13.4 10.78.737.306.234.954.043.39 0

25 0.19 0.43 0.81 1.51 2.83 4.08 5.28 6.46 8.73 11.0 12.1 14.2 16.3 17.0 14.2 11.3 9.25 7.76 6.62 5.26 4.30 3.60 0

26 0.20 0.46 0.85 1.58 2.95 4.25 5.51 6.74 9.10 11.4 12.6 14.8 17.0 18.1 15.1 12.0 9.85 8.21 7.03 5.57 4.57 3.83 0

28 0.22 0.49 0.92 1.72 3.20 4.61 5.98 7.30 9.85 12.4 13.7 16.0 18.4 20.1 16.9 13.4 11.0 9.18 7.83 6.23 5.10 4.27 0

30 0.23 0.53 0.99 1.85 3.45 4.97 6.44 7.83 10.70 13.5 14.7 17.3 19.8 22.4 18.7 14.8 12.2 10.2 8.73 6.91 5.65 0

32 0.25 0.57 1.06 1.98 3.70 5.33 6.90 8.43 11.4 14.3 15.7 18.6 21.3 24.0 20.7 16.4 13.4 11.3 9.62 7.61 6.23 0

35 0.28 0.63 1.17 2.19 4.07 5.86 7.61 9.33 12.6 15.7 17.3 20.4 23.5 26.5 23.6 18.7 15.4 12.8 11.0 8.73 7.12 0

40 0.32 0.72 1.35 2.52 4.71 6.77 8.80 10.70 14.5 18.2 20.0 23.6 27.1 30.6 28.9 22.9 18.7 15.7 13.4 10.7 0

45 0.36 0.82 1.54 2.86 5.34 7.68 10.0 12.2 16.5 20.7 22.8 26.8 30.8 34.6 34.4 27.3 22.4 18.7 16.0 0

Lubrication Method A B C

Lubrication Method A:Drop Lubrication B:Oil Bath Lubrication C:Forced Circulation Lubrication by Pump & It cannot be used for the selection of stainless steel.

999