Page 649 - IGUS Bearing

P. 649

iglidur clip bearings | Advantages iglidur clip bearings | Technical data

®

®

Solutions for stamped sheet metal

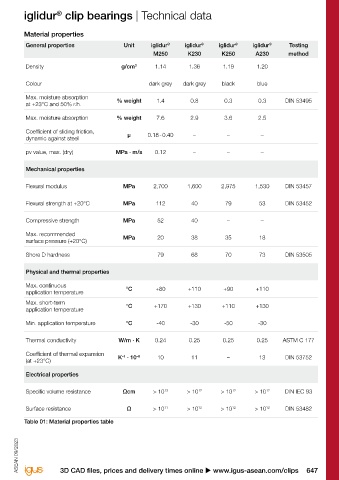

Material properties

iglidur clip bearings General properties Unit iglidur iglidur ® iglidur ® iglidur ® Testing

®

®

M250 K230 K250 A230 method

iglidur clip bearings: for fitting shafts

®

Captive with double flange Density g/cm 3 1.14 1.36 1.19 1.20

®

u From page 652 iglidur clip bearings are designed specifically for

fitting shafts through sheet metal. For this reason, Colour dark grey dark grey black blue

the bearings have flanges located on both ends. Max. moisture absorption

The plain bearings are secured in the sheet metal at +23°C and 50% r.h. % weight 1.4 0.8 0.3 0.3 DIN 53495

iglidur split bearings: plate on both sides after fitting.

®

Easy assembly due to lateral slot, The clip bearings have an angled slot which allows Max. moisture absorption % weight 7.6 2.9 3.6 2.5

also with anti-rotation feature them to be fitted from one side. After fitting, the Coefficient of sliding friction,

u From page 656 bearing expands and forms a lining for the hole dynamic against steel µ 0.18 - 0.40 – – –

in the metal plate. The shaft prevents the clip

bearing from falling out the housing. Even during pv value, max. (dry) MPa · m/s 0.12 – – –

linear movement, the plain bearing cannot slide out.

● Lateral slot for easy installation Mechanical properties

iglidur flanged bearings: ● Lubrication and maintenance-free

®

Press in and fold down ● Good adaptability to punched holes Flexural modulus MPa 2,700 1,600 2,975 1,530 DIN 53457

u From page 658 ● Abrasion-resistant

● Smooth operation Flexural strength at +20°C MPa 112 40 79 53 DIN 53452

● For rotating and linear movements

Compressive strength MPa 52 40 – –

Typical application areas Max. recommended

iglidur double flange bearings: ● Automotive industry surface pressure (+20°C) MPa 20 38 35 18

®

Press and plug ● Mechanical engineering

u From page 659 ● Jig construction Shore D hardness 79 68 70 73 DIN 53505

Physical and thermal properties

Max. continuous

Special solution application temperature °C +80 +110 +90 +110

iglidur Clip On: Max. short-term

®

Join and snap into place application temperature °C +170 +130 +110 +130

u From page 660

Min. application temperature °C -40 -30 -50 -30

Thermal conductivity W/m · K 0.24 0.25 0.25 0.25 ASTM C 177

Coefficient of thermal expansion K · 10 –5 10 11 – 13 DIN 53752

–1

(at +23°C)

Electrical properties

®

Available from stock Material: iglidur M250

Detailed information about delivery time online. 6 types Specific volume resistance Ωcm > 10 13 > 10 12 > 10 12 > 10 12 DIN IEC 93

Ø 3 - 25mm

Max. +80°C More dimensions upon request Surface resistance Ω > 10 11 > 10 12 > 10 12 > 10 12 DIN 53482

min. -40°C Table 01: Material properties table

Imperial dimensions available

u From page 1150

ASEAN 09/2023 ASEAN 09/2023

646 Online tools and more information u www.igus-asean.com/clips 3D CAD files, prices and delivery times online u www.igus-asean.com/clips 647