Page 837 - IGUS Bearing

P. 837

iglidur iglidur

®

®

®

®

tribo iglidur SLS | Laser sintering New iglidur triboresin | Product range New tribo

3D printing 3D printing

iglidur i10 for 3D printing via SLS iglidur i3000-PR for DLP and LCD printers

®

®

First 3D printing resin for wear-resistant

Chemical-resistant and food-compatible

special parts printed via SLS parts and gears ®

The laser sintering material iglidur i10 is ideal The DLP 3D printing resin iglidur i3000 is suitable for

®

for applications in the food and electroplating DLP and LCD printers and was specifically developed for

industries because of its chemical resistance. printing gears and wear-resistant parts. With a service

life of at least 30 to 60 times longer than conventional 3D

● Chemical-resistant printing resins, iglidur i3000 is suitable for all types of

®

● Food-compatible applications. The high resolution of up to 35μm enables

● Lubrication and maintenance-free the print of very delicate components with the finest details.

● Tough The mechanical properties are largely isotropic due to the

● Available with the 3D printing service from 7 days photopolymerisation process. Start of the beta test phase:

u www.igus-asean.com/idd

please contact igus if you would like to test individual wear-

®

5

resistant parts made from iglidur i3000.

®

Self-lubricating and low maintenance

●

4

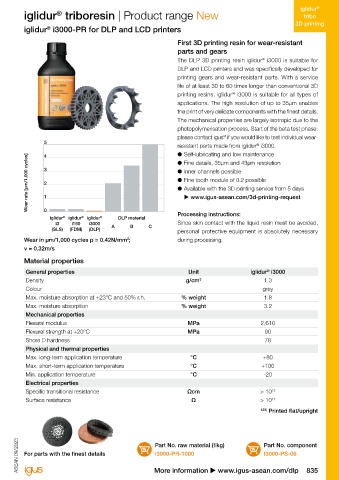

Wear rate [µm/1,000 cycles] 3 2 1 ● Inner channels possible

Fine details, 35µm and 43µm resolution

●

Fine tooth module of 0.2 possible

●

Available with the 3D printing service from 5 days

●

u www.igus-asean.com/3d-printing-request

0

iglidur iglidur iglidur DLP material Processing instructions:

®

®

®

i3 i150 i3000 A B C Since skin contact with the liquid resin must be avoided,

Delivery time (SLS) (FDM) (DLP) personal protective equipment is absolutely necessary

7 business days Wear in µm/1,000 cycles p = 0.42N/mm ; during processing.

2

v = 0.32m/s

Material properties Material properties

General properties 178) Unit iglidur i10 Testing method General properties Unit iglidur i3000

®

®

Density g/cm 3 0.85 Density g/cm 3 1.3

Colour off white Colour grey

Max. moisture absorption at +23°C/50% r.h. % weight 0.1 DIN 53495 Max. moisture absorption at +23°C and 50% r.h. % weight 1.8

Max. moisture absorption % weight 0.2 Max. moisture absorption % weight 3.2

Mechanical properties 178) Mechanical properties

Flexural modulus MPa 800/750 130) DIN 53457 Flexural modulus MPa 2,610

Flexural strength at +20°C MPa 20 130) DIN 53452 Flexural strength at +20°C MPa 90

Shore D hardness 66 DIN 53505 Shore D hardness 78

Physical and thermal properties Physical and thermal properties

Max. long-term application temperature °C +60 176), 177) Max. long-term application temperature °C +80

Max. short-term application temperature °C +80 176), 177) Max. short-term application temperature °C +100

Min. application temperature °C 0 Min. application temperature °C -20

Electrical properties Electrical properties

Specific transitional resistance Ωcm > 10 12 DIN IEC 93 Specific transitional resistance Ωcm > 10 12

Surface resistance Ω > 10 11 DIN 53482 Surface resistance Ω > 10 11

130) Printed flat/upright; 176) Relaxation not excluded; 177) Without additional load; no sliding movement; 130) Printed flat/upright

178) Depending on the printing parameters and building direction

u Chemical table, page 1170

Part No. raw material (10kg) Part No. component Part No. raw material (1kg) Part No. component

I10-PL-10000 I10-PS-02 ASEAN 09/2023 ASEAN 09/2023 For parts with the finest details I3000-PR-1000 I3000-PS-06

834 Online tools and more information u www.igus-asean.com/3d-printing-chemicals More information u www.igus-asean.com/dlp 835