Page 832 - IGUS Bearing

P. 832

iglidur iglidur

®

®

®

®

tribo iglidur SLS | Laser sintering iglidur SLS | Laser sintering tribo

3D printing 3D printing

iglidur i3 for 3D printing via SLS iglidur i6 for 3D printing via SLS

®

®

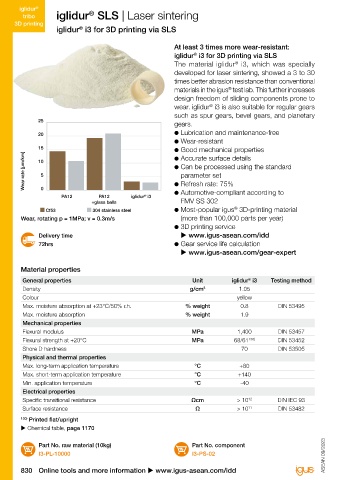

At least 3 times more wear-resistant: Durable worm wheels made of iglidur i6 via

®

iglidur i3 for 3D printing via SLS laser sintering

®

The material iglidur i3, which was specially The material iglidur i6 was specifically developed

®

®

developed for laser sintering, showed a 3 to 30 for laser sintering and is especially suited for worm

times better abrasion resistance than conventional wheels. The tests in the igus test laboratory

®

materials in the igus test lab. This further increases showed a longer service life than conventional

®

design freedom of sliding components prone to machined POM worm wheels. This greatly

wear. iglidur i3 is also suitable for regular gears increases the flexibility in the design of gears,

®

such as spur gears, bevel gears, and planetary since no tools are necessary due to the laser

25

gears. sintering process and gears can be produced

20 ● Lubrication and maintenance-free 1,200,000 efficiently without minimum order quantity.

● Wear-resistant ● New: Compliant with Regulation

15 ● Good mechanical properties 1,000,000 ● Excellent abrasion resistance

(EU) No. 10/2011 and FDA guidelines

Wear rate [µm/km] 10 ● Can be processed using the standard 600,000 ● Extremely long operating times

800,000

Accurate surface details

●

Lubrication and maintenance-free

parameter set

5

●

400,000

●

0

No tooling costs

Automotive-compliant according to

● Refresh rate: 75% Rotation cycle 200,000 ● Cost-effective, no minimum order quantity

●

PA12 PA12 iglidur i3

®

+glass balls FMV SS 302 0 ● Accurate surface details

®

®

Cf53 304 stainless steel ● Most-popular igus 3D-printing material PBT POM iglidur i6 ● 3D printing service

Wear, rotating p = 1MPa; v = 0.3m/s (more than 100,000 parts per year) Service life test worm wheel. 12rpm; 4.9Nm u www.igus-asean.com/idd

● 3D printing service ● Also suitable for medium-sized series,

Delivery time u www.igus-asean.com/idd Delivery time e.g. 5,000 pieces

72hrs ● Gear service life calculation 72hrs u www.igus-asean.com/gears

u www.igus-asean.com/gear-expert

Material properties Material properties

®

General properties Unit iglidur i3 Testing method General properties Unit iglidur i6 Testing method

®

Density g/cm 3 1.05 Density g/cm 3 1.06

Colour yellow Colour white

Max. moisture absorption at +23°C/50% r.h. % weight 0.8 DIN 53495 Max. moisture absorption at +23°C/50% r.h. % weight 0.8 DIN 53495

Max. moisture absorption % weight 1.9 Max. moisture absorption % weight 1.9

Mechanical properties Mechanical properties

Flexural modulus MPa 1,400 DIN 53457 Flexural modulus MPa 1,100 DIN 53457

Flexural strength at +20°C MPa 68/61 130) DIN 53452 Flexural strength at +20°C MPa 49/38 130) DIN 53452

Shore D hardness 70 DIN 53505 Shore D hardness 67 DIN 53505

Physical and thermal properties Physical and thermal properties

Max. long-term application temperature °C +80 Max. long-term application temperature °C +80

Max. short-term application temperature °C +140 Max. short-term application temperature °C +140

Min. application temperature °C -40 Min. application temperature °C -40

Electrical properties Electrical properties

Specific transitional resistance Ωcm > 10 12 DIN IEC 93 Specific transitional resistance Ωcm > 10 12 DIN IEC 93

Surface resistance Ω > 10 11 DIN 53482 Surface resistance Ω > 10 11 DIN 53482

130) Printed flat/upright 130) Printed flat/upright

u Chemical table, page 1170 u Chemical table, page 1170

Part No. raw material (10kg) Part No. component Part No. raw material (10kg) Part No. component

I3-PL-10000 I3-PS-02 ASEAN 09/2023 ASEAN 09/2023 I6-PL-10000 I6-PS-02

830 Online tools and more information u www.igus-asean.com/idd Prices and delivery time online u www.igus-asean.com/idd 831