Page 831 - IGUS Bearing

P. 831

iglidur iglidur

®

®

®

®

®

tribo iglidur tribo 3D printing | Tested iglidur tribofilament | Test results tribo

3D printing 3D printing

Printed as good as injection-moulded

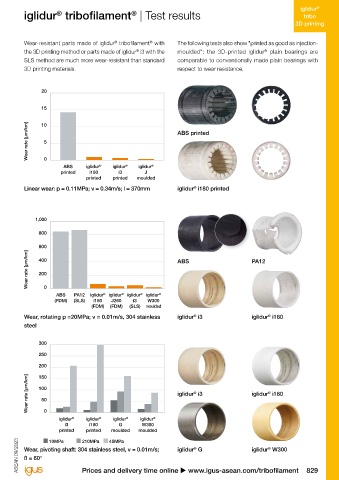

iglidur 3D printing materials impress in Wear-resistant parts made of iglidur tribofilament with The following tests also show "printed as good as injection-

®

®

®

testing with injection-moulded quality the 3D printing method or parts made of iglidur i3 with the moulded": the 3D-printed iglidur plain bearings are

®

®

The igus test series prove that 3D-printed bearings made SLS method are much more wear-resistant than standard comparable to conventionally made plain bearings with

®

from iglidur tribo materials are just as wear-resistant as 3D printing materials. respect to wear resistance.

®

injection-moulded and machined parts. The tests have

also shown that iglidur 3D printing filaments, 3D printing

®

resins and SLS materials have significantly lower coefficient 20

of friction and up to 50 times higher abrasion resistance

than conventional 3D printing materials. This makes igus 15

®

3D printing materials the only ones that are convincing even

in moving applications. You can directly install printed parts 10

such as plain bearings, drive nuts or worm gears and use ABS printed

them as wear-resistant parts - from the prototype phase Wear rate [µm/km] 5

to series production. 0

ABS iglidur iglidur iglidur

®

®

®

printed i180 i3 J

printed printed moulded

Linear wear: p = 0.11MPa; v = 0.34m/s; l = 370mm iglidur i180 printed

®

50 1,000

45

40 800

35

30 600

Wear rate [µm/km] 20 5 3.0 3.0 2.0 2.0 0.7 2.0 10.0 15.0 279.0 269.0 66.0 49.0 20.0 14.0 24.0 26.0 Wear rate [µm/km] 400 ABS PA12

25

15

200

10

0

iglidur iglidur iglidur PA12 ABS PA66 POM PA66 0 ABS PA12 iglidur iglidur iglidur iglidur

®

®

®

®

®

®

®

i3 i150 i190 (SLS) (FDM) (moulded) (machined) (machined) (FDM) (SLS) i180 J260 i3 W300

(SLS) (FDM) (FDM) (FDM) (FDM) (SLS) moulded

®

®

Cf53 304 stainless steel Wear, rotating p =20MPa; v = 0.01m/s, 304 stainless iglidur i3 iglidur i180

Wear, 60° pivoting, p = 2MPa; v = 0.01m/s steel

50 300

45 250

40

35 200

30 150

Wear rate [µm/km] 20 5 2.0 4.0 1.2 0.4 2.0 2.0 10,000 8.0 95.0 163.0 104.0 47.0 4.0 1.2 57.0 9,999 Wear rate [µm/km] 100 iglidur i3 iglidur i180

25

15

®

®

10

50

0

iglidur iglidur iglidur PA12 ABS PA66 POM PA66 0 iglidur iglidur iglidur iglidur

®

®

®

®

®

®

®

i3 i150 i190 (SLS) (FDM) (moulded) (machined) (m) i3 i180 G W300

(SLS) (FDM) (FDM) printed printed moulded moulded

Cf53 304 stainless steel 10MPa 210MPa 45MPa

Wear, linear p = 1MPa; v = 0.01m/s ASEAN 09/2023 ASEAN 09/2023 Wear, pivoting shaft: 304 stainless steel, v = 0.01m/s; iglidur G iglidur W300

®

®

ß = 60°

828 Online tools and more information u www.igus-asean.com/idd Prices and delivery time online u www.igus-asean.com/tribofilament 829