Page 834 - IGUS Bearing

P. 834

iglidur iglidur

®

®

®

®

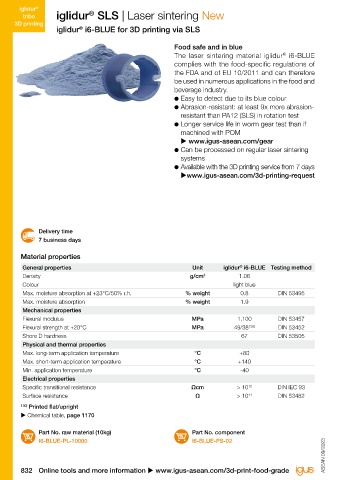

tribo iglidur SLS | Laser sintering New iglidur SLS | Laser sintering New tribo

3D printing 3D printing

iglidur i6-BLUE for 3D printing via SLS iglidur i8 for 3D printing via SLS

®

®

Food safe and in blue Components with ESD properties

The laser sintering material iglidur i6-BLUE iglidur i8 is an electrostatically dissipative SLS

®

®

complies with the food-specific regulations of material for long-lasting and abrasion-resistant

the FDA and of EU 10/2011 and can therefore 3D printed components. Ideal for applications

be used in numerous applications in the food and where ESD properties are essential to operate

beverage industry. within electronic components: also the perfect

● Easy to detect due to its blue colour choice for the manufacture of anti-static parts for

● Abrasion-resistant: at least 9x more abrasion- machines that require ATEX certification.

resistant than PA12 (SLS) in rotation test ● Electrostatically dissipative (ESD) and black

● Longer service life in worm gear test than if 100 ● Excellent service life – for example, a pivoting

machined with POM 80 abrasion resistance factor of 2 compared to

u www.igus-asean.com/gear PA 12, can be calculated online

● Can be processed on regular laser sintering 60 ● Can be processed on regular and low-cost

systems 40 laser sintering systems

● Available with the 3D printing service from 7 days ● 3D printing service:

uwww.igus-asean.com/3d-printing-request Wear rate [µm/km] 20 u www.igus-asean.com/idd

0 ● Gear service life calculation

®

®

PA12 iglidur i8-ESD iglidur i3 u www.igus-asean.com/gear-expert

Cf53 304 stainless steel

Wear, linear p = 1MPa; v = 0.01m/s

Delivery time Delivery time

7 business days 4 business days

Material properties Material properties

General properties Unit iglidur i6-BLUE Testing method General properties Unit iglidur i8-ESD Testing method

®

®

Density g/cm 3 1.06 Density g/cm 3 1.03

Colour light blue Colour black

Max. moisture absorption at +23°C/50% r.h. % weight 0.8 DIN 53495 Max. moisture absorption at +23°C/50% r.h. % weight 0.8 DIN 53495

Max. moisture absorption % weight 1.9 Max. moisture absorption % weight 1.9

Mechanical properties Mechanical properties

Flexural modulus MPa 1,100 DIN 53457 Flexural modulus MPa 2,200 DIN 53457

Flexural strength at +20°C MPa 49/38 130) DIN 53452 Flexural strength at +20°C MPa 63/42 130) DIN 53452

Shore D hardness 67 DIN 53505 Shore D hardness 72 DIN 53505

Physical and thermal properties Physical and thermal properties

Max. long-term application temperature °C +80 Max. long-term application temperature °C +80

Max. short-term application temperature °C +140 Max. short-term application temperature °C +140

Min. application temperature °C -40 Min. application temperature °C -40

Electrical properties Electrical properties

Specific transitional resistance Ωcm > 10 12 DIN IEC 93 Specific transitional resistance Ωcm 2.8 x 10 7 DIN IEC 93

Surface resistance Ω > 10 11 DIN 53482 Surface resistance Ω 3.6 x 10 7 DIN 53482

130) Printed flat/upright 130) Printed flat/upright

u Chemical table, page 1170 u Chemical table, page 1170

Part No. raw material (10kg) Part No. component Part No. raw material (10kg) Part No. component

I6-BLUE-PL-10000 I6-BLUE-PS-02 I8-ESD-PL-10000 I8-ESD-PS-02

ASEAN 09/2023 ASEAN 09/2023 Part No. raw material (1kg)

I8-ESD-PL-1000

832 Online tools and more information u www.igus-asean.com/3d-print-food-grade Online tools and more information u www.igus-asean.com/i8-ESD 833