Page 458 - IGUS Linear

P. 458

®

dryspin dryspin technology | Lead screw nuts | Product range dryspin

®

®

technology technology

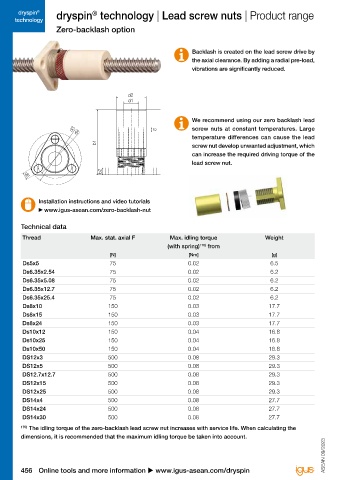

Zero-backlash option

Order key

Backlash is created on the lead screw drive by

the axial clearance. By adding a radial pre-load,

vibrations are significantly reduced. Part number Type Thread

d2

d1

We recommend using our zero backlash lead

d3 d4 3 screw nuts at constant temperatures. Large

temperature differences can cause the lead dryspin ® technology Direction of rotation

b1 screw nut develop unwanted adjustment, which Zero-Backlash Thread type Thread Ø [mm] Yellow markings show the axial

can increase the required driving torque of the iglidur ® J Form F Metric Type 0001 Pitch clearance of a standard lead

lead screw nut. screw nut

b2

d5

The lead screw nut consists of a support nut, an adjusting ring with torsion spring, a friction

disc and the axial element. With the help of the torsion spring, the pretension is brought

Installation instructions and video tutorials into the lead screw system.

www.igus-asean.com/zero-backlash-nut

Technical data Dimensions [mm]

Thread Max. stat. axial F Max. idling torque Weight d1 156) d2 156) d3 d4 d5 b1 40) 156) b2 Part No.

(with spring) 170) from

[N] [Nm] [g]

Ds5x5 75 0.02 6.5 5 13.5 28 22.2 3.7 31 - 36 4.1 DST-JFRM-ZB-0001-DS5X5

Ds6.35x2.54 75 0.02 6.2 6.35 13.5 28 22.2 3.7 31 - 36 4.1 DST-JFRM-ZB-0001-DS6.35X2.54

Ds6.35x5.08 75 0.02 6.2 6.35 13.5 28 22.2 3.7 31 - 36 4.1 DST-JFRM-ZB-0001-DS6.35X5.08

Ds6.35x12.7 75 0.02 6.2 6.35 13.5 28 22.2 3.7 31 - 36 4.1 DST-JFRM-ZB-0001-DS6.35X12.7

Ds6.35x25.4 75 0.02 6.2 6.35 13.5 28 22.2 3.7 31 - 36 4.1 DST-JFRM-ZB-0001-DS6.35X25.4

Ds8x10 150 0.03 17.7 8 20 38.1 28.3 5.2 41 - 47 4.8 DST-JFRM-ZB-0001-DS8X10

Ds8x15 150 0.03 17.7 8 20 38.1 28.3 5.2 41 - 47 4.8 DST-JFRM-ZB-0001-DS8X15

Ds8x24 150 0.03 17.7 8 20 38.1 28.3 5.2 41 - 47 4.8 DST-JFRM-ZB-0001-DS8X24

Ds10x12 150 0.04 16.8 10 20 38.1 28.3 5.2 41 - 47 4.8 DST-JFRM-ZB-0001-DS10X12

Ds10x25 150 0.04 16.8 10 20 38.1 28.3 5.2 41 - 47 4.8 DST-JFRM-ZB-0001-DS10X25

Ds10x50 150 0.04 16.8 10 20 38.1 28.3 5.2 41 - 47 4.8 DST-JFRM-ZB-0001-DS10X50

DS12x3 500 0.08 29.3 12 24 41.2 31.8 5.2 55 - 61 7.0 DST-JFRM-ZB-0001-DS12X3 New

DS12x5 500 0.08 29.3 12 24 41.2 31.8 5.2 55 - 61 7.0 DST-JFRM-ZB-0001-DS12X5 New

DS12.7x12.7 500 0.08 29.3 12 24 41.2 31.8 5.2 55 - 61 7.0 DST-JFRM-ZB-0001-DS12.7X12.7 New

DS12x15 500 0.08 29.3 12 24 41.2 31.8 5.2 55 - 62 7.0 DST-JFRM-ZB-0001-DS12X15 New

DS12x25 500 0.08 29.3 12 24 41.2 31.8 5.2 55 - 63 7.0 DST-JFRM-ZB-0001-DS12X25 New

DS14x4 500 0.08 27.7 14 24 41.2 31.8 5.2 55 - 64 7.0 DST-JFRM-ZB-0001-DS14X4 New

DS14x24 500 0.08 27.7 14 24 41.2 31.8 5.2 55 - 65 7.0 DST-JFRM-ZB-0001-DS14X24 New

DS14x30 500 0.08 27.7 14 24 41.2 31.8 5.2 55 - 66 7.0 DST-JFRM-ZB-0001-DS14X30 New

170) The idling torque of the zero-backlash lead screw nut increases with service life. When calculating the 40) Variable according to thread pitch / clearance

dimensions, it is recommended that the maximum idling torque be taken into account. 156) Tolerances according to DIN ISO 2768-1, tolerance class m (medium)

ASEAN 09/2023 ASEAN 09/2023

456 Online tools and more information u www.igus-asean.com/dryspin 3D CAD files, prices and delivery time online u www.igus-asean.com/dryspin 457