Page 327 - ASEAN Chainflex Catalogue 2023

P. 327

CF886 PVC iguPUR PUR TPE Basic requirements low 1 2 3 4 5 6 7 highest CF886

PVC Travel distance unsupported 1 2 3 4 5 6 ≥ 400m PVC

15 x d ® Oil resistance none 1 2 3 4 highest 15 x d

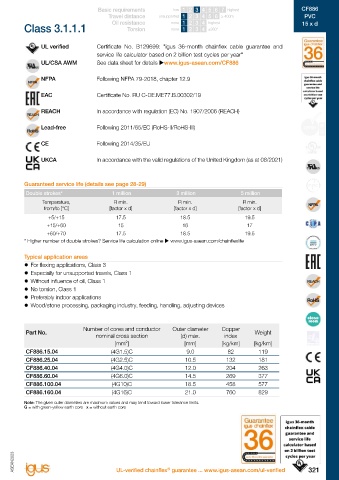

Motor cable | PVC | chainflex CF886 Class 3.1.1.1 Torsion none 1 2 3 4 ±360°

5,000,000 15 x d 10m UL verified Certificate No. B129699: "igus 36-month chainflex cable guarantee and

service life calculator based on 2 billion test cycles per year"

Double strokes guaranteed Bend radius, e-chain ® Travel distance, e-chain ®

UL/CSA AWM See data sheet for details www.igus-asean.com/CF886

z For flexing applications NFPA Following NFPA 79-2018, chapter 12.9

z PVC outer jacket

z Shielded EAC Certificate No. RU C-DE.ME77.B.00302/19

z Flame-retardant

REACH In accordance with regulation (EC) No. 1907/2006 (REACH)

Dynamic information Lead-free Following 2011/65/EC (RoHS-II/RoHS-III)

®

Bend radius e-chain linear minimum 15 x d

flexible minimum 12 x d CE Following 2014/35/EU

fixed minimum 8 x d

Temperature e-chain linear +5°C up to +70°C UKCA In accordance with the valid regulations of the United Kingdom (as at 08/2021)

®

flexible -5°C up to +70°C (following DIN EN 60811-504)

fixed -15°C up to +70°C (following DIN EN 50305)

v max. unsupported 3m/s Guaranteed service life (details see page 28-29)

Double strokes* 1 million 3 million 5 million

a max. 20m/s² Temperature, R min. R min. R min.

from/to [°C] [factor x d] [factor x d] [factor x d]

Travel distance Unsupported travels up to 10m, Class 1 +5/+15 17.5 18.5 19.5

+15/+60 15 16 17

Cable structure +60/+70 17.5 18.5 19.5

Conductor Conductor consisting of bare copper wires (according to DIN EN 60228). * Higher number of double strokes? Service life calculation online www.igus-asean.com/chainflexlife

Core insulation Mechanically high-quality, especially low-capacitance TPE mixture. Typical application areas

z For flexing applications, Class 3

Core structure Cores wound with an optimised pitch length. z Especially for unsupported travels, Class 1

z Without influence of oil, Class 1

Core identification Black cores with white numbers, one green-yellow core. z No torsion, Class 1

1. Core: U / L1 / C / L+ z Preferably indoor applications

2. Core: V / L2 z Wood/stone processing, packaging industry, feeding, handling, adjusting devices

3. Core: W / L3 / D / L-

Overall shield Braiding made of tinned copper wires.

Coverage approx. 60% optical Part No. Number of cores and conductor Outer diameter Copper Weight

®

Outer jacket Low-adhesion PVC mixture, adapted to suit the requirements in e-chains . nominal cross section (d) max. index

Colour: Pastel orange (similar to RAL 2003) [mm²] [mm] [kg/km] [kg/km]

CF886.15.04 (4G1.5)C 9.0 82 119

Electrical information CF886.25.04 (4G2.5)C 10.5 132 181

Nominal voltage 600/1,000V (following DIN VDE 0298-3) CF886.40.04 (4G4.0)C 12.0 204 263

1,000V (following UL) CF886.60.04 (4G6.0)C 14.5 269 377

Testing voltage 4,000V (following DIN EN 50395) CF886.100.04 (4G10)C 18.5 458 577

CF886.160.04 (4G16)C 21.0 760 829

Properties and approvals Note: The given outer diameters are maximum values and may tend toward lower tolerance limits.

Flame-retardant According to IEC 60332-1-2, Cable Flame, VW-1, FT1, FT2 / Horizontal Flame G = with green-yellow earth core x = without earth core

Example image Silicone-free Free from silicone which can affect paint adhesion (following PV 3.10.7 – status

1992)

EPLAN download, configurators www.igus-asean.com/CF886

320 36-month guarantee ... more than 1,350 cable types from stock ... no cutting charges ASEAN2023 ASEAN2023 UL-verified chainflex guarantee ... www.igus-asean.com/ul-verified 321

®