Page 167 - IGUS Linear

P. 167

drylin T rail guides | Design rules drylin T rail guides | Technical data

®

®

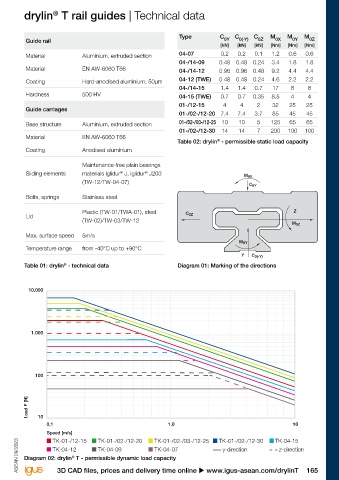

Design tip Version with floating bearing in z-direction Guide rail Type C 0Y C 0(-Y) C 0Z M 0X M 0Y M 0Z

The compensation of parallelism errors up to a maximum [kN] [kN] [kN] [Nm] [Nm] [Nm]

of 0.5mm between mounted rails is possible with a fixed/ 1 Rail Material Aluminium, extruded section 04-07 0.2 0.2 0.1 1.2 0.6 0.6

floating bearing. During installation, take care that the 2 Sliding elements Material EN AW-6060 T66 04-/14-09 0.48 0.48 0.24 3.4 1.8 1.8

floating bearing has approximately the same clearance on 3 Carriage with fixed bearings 04-/14-12 0.96 0.96 0.48 9.2 4.4 4.4

both sides. 4 Carriage with floating bearings Coating Hard-anodised aluminium, 50µm 04-12 (TWE) 0.48 0.48 0.24 4.6 2.2 2.2

In the adjacent designs you can see the version of the fixed/ LLZ or LLY Hardness 500 HV 04-/14-15 1.4 1.4 0.7 17 8 8

floating bearing system recommended by us. 04-15 (TWE) 0.7 0.7 0.35 8.5 4 4

The mounting surfaces of the rails and guide carriages Guide carriages 01-/12-15 4 4 2 32 25 25

should be very flat (e.g. machined surface) to prevent 01-/02-/12-20 7.4 7.4 3.7 85 45 45

twisting in the system. Small discrepancies in the mounting Horizontal version with floating bearing in z-direction Base structure Aluminium, extruded section 01-/02-/03-/12-25 10 10 5 125 65 65

surfaces can be compensated up to a certain amount Material EN AW-6060 T66 01-/02-/12-30 14 14 7 200 100 100

(0.5mm) by a greater clearance adjustment. The clearance Table 02: drylin - permissible static load capacity

®

adjustment is possible only in unloaded state. If you have Coating Anodised aluminium

any questions on design and/or assembly, please make

use of our technical support. Horizontal version with floating bearing in the Maintenance-free plain bearings

®

®

y-direction and lateral guide carriage Sliding elements materials iglidur J, iglidur J200 M 0X

Technical details on floating bearings (TW-12/TW-04-07)

u Page 50 C 0Y

The 2:1 Rule u Page 50 Bolts, springs Stainless steel

Plastic (TW-01/TWA-01), steel C 0Z Z

Installation drylin T linear guide system Lid (TW-02)/TW-03/TW-12

®

Make sure to assemble the side of the carriage saying M 0Z

"Reset Clearance" onto the rail first (see picture). Max. surface speed 5m/s

M 0Y

Temperature range from -40°C up to +90°C

Y C 0(-Y)

Table 01: drylin - technical data Diagram 01: Marking of the directions

®

10.000

1.000

TW series, adjustable clearance TWA series, automatic

Tightening torque for drylin metallic screws Floating bearing clearances for drylin T

®

®

Metric thread tightening Recommended miniature guides

(Da) torque tightening torque LLZ: Floating bearing in z-direction 100

[Nm] [Nm] LLY: Floating bearing in y-direction

M3 0.5 - 1.1 0.7

M4 1.0 - 2.8 1.5 Floating TW-04-07 TW-04-09 TW-04-12 TW-04-15

M5 2.0 - 5.5 3.0 bearing Load F [N]

M6 4.0 - 10.0 6.0 clearances 10

M8 8.0 - 23.0 15.0 LLY – 0.4 0.5 0.7 0,1 1,0 10

M10 22.0 - 46.0 30.0 LLZ 0.4 0.4 0.5 0.7 Speed [m/s]

Minimal screw-in depth for aluminium and zinc TK-01-/12-15 TK-01-/02-/12-20 TK-01-/02-/03-/12-25 TK-01-/02-/12-30 TK-04-15

TK-04-07

TK-04-12

TK-04-09

die-casting parts: 1.5 x Da ASEAN 09/2023 ASEAN 09/2023 Diagram 02: drylin T - permissible dynamic load capacity y-direction z-direction

®

164 Online tools and more information u www.igus-asean.com/drylinT 3D CAD files, prices and delivery time online u www.igus-asean.com/drylinT 165